Auto Multi-Cartridge Back Flush Industrial Water Filters

Basic Info

Model No.: YLF-200

Product Description

Model NO.: YLF-200 Usage: Environmental Protection, Chemical Industry Style: Vertical Certification: CE Material: Carbon Steel/Stainless Steel Inlet and Outlet: Dn300mm/12 Inch Working Pressure: Less Than 1.0 MPa Pressure Loss: Less Than 0.015MPa Interface: Flange Specification: CE, SGS HS Code: 8421219990 Type: Filter Motive Force: Pressure Performance: Efficient Filtration Product Name: Multi-Cartridge Self-Cleaning Filter Flow Rate: 450m3/H Drain Diameter: Dn100mm Working Temperature: Less Than 100 Centigrade Filtering Precision: 20-500mm Trademark: YLD Origin: Jiangyin, Jiangsu, China Auto Multi-Cartridge Back Flush Industrial Water Filters

Filtration

The multiple cartridge backwash system is a fully automated filter system that removes or collects suspended solids from a liquid process stream. This systems' high efficiency operation can improve product quality, maximize solids recovery and protect equipment, operators and the environment.

Cleaning Process

MANUAL vs. AUTOMATIC

Use automatic systems for maximum waste reduction with unattended service. Cleaning is controlled by changes in differential pressure across the filter media. As solids build up on the media, the differential pressure increases. When it reaches a preset level, the filter system automatically starts to clean the media.Manual systems are available where attended service is desired.

Application Fields

Power Plants : Treatment of Industrial Water for cooling generators and filtration of

sealing water to increase the service life of the Turbine Shaft sliding-ring seals in

Hydro-Electric Power Stations.

Steel Industry: Protection of nozzles and pumps during high-pressure descaling, water

treatment for blast furnaces, rolling mills, cleaning, quenching applications.

Chemical Industry : Improvement of product quality by filtering process media. Filtration

of White water, Black Liquor, Starch, Fuel oils, Caustic Solutions, Cooking oils,

brackish/salt intake water etc. For filtration of water used for cooling, process, fire

protection applications.

Pulp & Paper Industry : Removal of fibers from white water filtrate, Protection of spray

nozzles for screens of paper making machines. This reduces frequent failures caused due to

clogging and wear.

Mining: By filtering underground, spray water of even quality is assured. This results in

more reliable operation of pumps and disc cutting machines

Environmental Technology. Used as pre-filters before waste Water Treatment plants, UV

Treatment, Reverse Osmosis, membrane filtration etc.

Sewage Treatment Plants : During Production of industrial water, filtration of a take off

of the clear run can be used to save valuable drinking or well water.

Heat Transfer / Heat Supply : Protects heat Exchangers from clogging & wear

Chracteristics of SS multi-cartridge Automatic Backwash Filter

a.it is usually used in large flow rate water with high filtration degree ,such as 50-100 micros.

b.there will be 5 to 20 or more pcs SS filter cartridges inside the filter.

c.after one day working,all filter cartridges will be backwashed by setted parameters or pressure control.

the particles which intercepted and accumulated on cartridge will be washed away.

during backwash processing,drain valve will open and particles will be outfall .

for example,backwash time for each cartdiegs will last 10 to 20 seconds.

if there are 10 pcs of SS cartridge ,backwash time will be 220 to 240 seconds.

d. after backwash,the filter will come to next filter period(usually it is 24 hours).

e.you could set the backwash circle as per practical requirement,such as twice or 3 times every 24 hours.

Important parts for filtration system:

01. Carbon steel cycloner,

02. Stainless screen,

03. Butterfly valve

04. Sewage device, etc.

Technical Parameters:

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cartridge Filter、Filter Cartridge. If these products fail to match your need, please contact us and we would like to provide relevant information.

Filtration

The multiple cartridge backwash system is a fully automated filter system that removes or collects suspended solids from a liquid process stream. This systems' high efficiency operation can improve product quality, maximize solids recovery and protect equipment, operators and the environment.

Cleaning Process

MANUAL vs. AUTOMATIC

Use automatic systems for maximum waste reduction with unattended service. Cleaning is controlled by changes in differential pressure across the filter media. As solids build up on the media, the differential pressure increases. When it reaches a preset level, the filter system automatically starts to clean the media.Manual systems are available where attended service is desired.

Application Fields

Power Plants : Treatment of Industrial Water for cooling generators and filtration of

sealing water to increase the service life of the Turbine Shaft sliding-ring seals in

Hydro-Electric Power Stations.

Steel Industry: Protection of nozzles and pumps during high-pressure descaling, water

treatment for blast furnaces, rolling mills, cleaning, quenching applications.

Chemical Industry : Improvement of product quality by filtering process media. Filtration

of White water, Black Liquor, Starch, Fuel oils, Caustic Solutions, Cooking oils,

brackish/salt intake water etc. For filtration of water used for cooling, process, fire

protection applications.

Pulp & Paper Industry : Removal of fibers from white water filtrate, Protection of spray

nozzles for screens of paper making machines. This reduces frequent failures caused due to

clogging and wear.

Mining: By filtering underground, spray water of even quality is assured. This results in

more reliable operation of pumps and disc cutting machines

Environmental Technology. Used as pre-filters before waste Water Treatment plants, UV

Treatment, Reverse Osmosis, membrane filtration etc.

Sewage Treatment Plants : During Production of industrial water, filtration of a take off

of the clear run can be used to save valuable drinking or well water.

Heat Transfer / Heat Supply : Protects heat Exchangers from clogging & wear

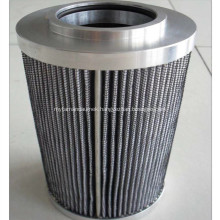

Chracteristics of SS multi-cartridge Automatic Backwash Filter

a.it is usually used in large flow rate water with high filtration degree ,such as 50-100 micros.

b.there will be 5 to 20 or more pcs SS filter cartridges inside the filter.

c.after one day working,all filter cartridges will be backwashed by setted parameters or pressure control.

the particles which intercepted and accumulated on cartridge will be washed away.

during backwash processing,drain valve will open and particles will be outfall .

for example,backwash time for each cartdiegs will last 10 to 20 seconds.

if there are 10 pcs of SS cartridge ,backwash time will be 220 to 240 seconds.

d. after backwash,the filter will come to next filter period(usually it is 24 hours).

e.you could set the backwash circle as per practical requirement,such as twice or 3 times every 24 hours.

Important parts for filtration system:

01. Carbon steel cycloner,

02. Stainless screen,

03. Butterfly valve

04. Sewage device, etc.

Technical Parameters:

| Model | Flow (T/h) | Inlet and outlet diameter (mm) | Drainage diameter (mm) | D (mm) | H (mm) | H1 (mm) | H2 (mm) |

| YLF-50 | 28 | DN50 | DN50 | 300 | 1690 | 265 | 640 |

| YLF-80 | 50 | DN80 | DN50 | 350 | 1720 | 265 | 660 |

| YLF-100 | 80 | DN100 | DN50 | 400 | 1760 | 265 | 680 |

| YLF-200 | 200 | DN200 | DN80 | 500 | 1860 | 290 | 715 |

| YLF-250 | 280 | DN250 | DN80 | 600 | 1930 | 290 | 755 |

| YLF-300 | 450 | DN300 | DN100 | 700 | 2040 | 335 | 755 |

| YLF-350 | 600 | DN350 | DN100 | 800 | 2105 | 335 | 770 |

| YLF-400 | 800 | DN400 | DN100 | 1000 | 2220 | 335 | 800 |

| YLF-500 | 1000 | DN500 | DN100 | 1200 | 2360 | 365 | 825 |

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cartridge Filter、Filter Cartridge. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Filter > Automatic Backwash Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)