Automatic Back Washing Strainer Water Filter

Basic Info

Model No.: YLF-400

Product Description

Model NO.: YLF-400 Usage: Environmental Protection, Chemical Industry Style: Vertical Certification: CE Material: Carbon Steel/Stainless Steel Inlet and Outlet: Dn250mm/10 Inch Working Pressure: Less Than 1.0 MPa Pressure Loss: Less Than 0.015MPa Interface: Flange Specification: CE, SGS HS Code: 8421219990 Type: Filter Motive Force: Pressure Performance: Efficient Filtration Product Name: Multi-Cartridge Self-Cleaning Filter Flow Rate: 280m3/H Drain Diameter: Dn80mm Working Temperature: Less Than 100 Centigrade Filtering Precision: 20-500mm Trademark: YLD Origin: Jiangyin, Jiangsu, China

Automatic Back Washing Strainer Water Filter

- Filter system for fine particles and turbidities

- Filter pore size 1 μm to 150 μm

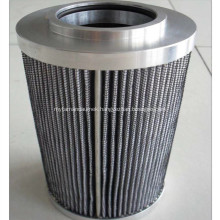

- Filter mesh of stainless steel

- All materials suitable for use with water and food

- Backwash without interruption of filtration

- Minimum amount of backwash medium needed

- Different body sizes for flow rates 20 bis 600 m3/h

- Quick installation, no start-up time

- Space saving construction

- Easy maintenance

- Medium: Raw water, surface water, waste water

- Max. operating pressure:

- DN 50: 16 bar

- DN 150 - 300: 10 bar

- Nominal sizes: DN 50 bis DN 350

Working principle

Liquid into the filter via the water inlet, Impurities is deposited on the stainless steel mesh, Filtered clean water from the outlet flow out, With the accumulation of impurities inside the cartridge, the filter cake formed in the surface of the cartridge, which leads to gradually pressure , drop increasing between the inlet and outlet ,it begin the automatic cleaning process, when the pressure reaches the default .

The automatic self cleaning finished by rotating cleaning brush and switching the drain valve .open the drain valve is blocked so that a negative pressure within the cartridge, the cartridge attached to the inner wall of the filter cake was cleaning brush cleaning off the relationship because of negative pressure through the sewage discharge valve in this body. The cleaning process is within 60 seconds, the system continues to flow cleaning.

Application

Filtration products has been used widely in variety aspects , In lots of project which refer to the solid/liquid/ separation ,Such as :

Water treating, Raw water treating , Recycle water , Chilling water treat

Agricultural irrigation ,such as Farms Water , Golf Water Filtration , Orchards and Groves Water Filtration , Vineyard Water Filtration etc .

Papermaking factory

Steel and lron plant

Petroleum Chemistry

Chracteristics of SS multi-cartridge Automatic Backwash Filter

automatic backwashing self-cleaning filter suitable for demanding environments, for different application requirements ,3500micron -50micron filter screens are available.with 8"-36" inlet/outlet diameter. The self-cleaning filtration is started by a differential pressure switch which is monitoring the pressure difference on the filter inlet and outlet.

Continuity water supply: very less cleaning water requirement ,just 1% of the out water.the flushing time is2-15 seconds, and the whole system is continuity water supply.

High filtration precision: the filtration precision can be up to 20 microns, with a variety of precision filter screens.

Large filtration area: the standard effective filtration area is larger 7 to 40 times than the entrance area.

Reliable cleaning: there are a variety of control modes, such as manual, pressure difference , time, setting and PLC program logic control .

Low-cost and simple installation: various structure forms, suitable for installation various of conditions.

Long service life: more than 10 years ; the filter screen is made of stainless steel, and if necessary, the filter screens of different specifications can easily be replaced.

Important parts for filtration system:

01. Carbon steel cycloner,

02. Stainless screen,

03. Butterfly valve

04. Sewage device, etc.

Technical Parameters:

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cartridge Filter、Filter Cartridge. If these products fail to match your need, please contact us and we would like to provide relevant information.

Automatic Back Washing Strainer Water Filter

- Filter system for fine particles and turbidities

- Filter pore size 1 μm to 150 μm

- Filter mesh of stainless steel

- All materials suitable for use with water and food

- Backwash without interruption of filtration

- Minimum amount of backwash medium needed

- Different body sizes for flow rates 20 bis 600 m3/h

- Quick installation, no start-up time

- Space saving construction

- Easy maintenance

- Medium: Raw water, surface water, waste water

- Max. operating pressure:

- DN 50: 16 bar

- DN 150 - 300: 10 bar

- Nominal sizes: DN 50 bis DN 350

Working principle

Liquid into the filter via the water inlet, Impurities is deposited on the stainless steel mesh, Filtered clean water from the outlet flow out, With the accumulation of impurities inside the cartridge, the filter cake formed in the surface of the cartridge, which leads to gradually pressure , drop increasing between the inlet and outlet ,it begin the automatic cleaning process, when the pressure reaches the default .

The automatic self cleaning finished by rotating cleaning brush and switching the drain valve .open the drain valve is blocked so that a negative pressure within the cartridge, the cartridge attached to the inner wall of the filter cake was cleaning brush cleaning off the relationship because of negative pressure through the sewage discharge valve in this body. The cleaning process is within 60 seconds, the system continues to flow cleaning.

Application

Filtration products has been used widely in variety aspects , In lots of project which refer to the solid/liquid/ separation ,Such as :

Water treating, Raw water treating , Recycle water , Chilling water treat

Agricultural irrigation ,such as Farms Water , Golf Water Filtration , Orchards and Groves Water Filtration , Vineyard Water Filtration etc .

Papermaking factory

Steel and lron plant

Petroleum Chemistry

Chracteristics of SS multi-cartridge Automatic Backwash Filter

automatic backwashing self-cleaning filter suitable for demanding environments, for different application requirements ,3500micron -50micron filter screens are available.with 8"-36" inlet/outlet diameter. The self-cleaning filtration is started by a differential pressure switch which is monitoring the pressure difference on the filter inlet and outlet.

Continuity water supply: very less cleaning water requirement ,just 1% of the out water.the flushing time is2-15 seconds, and the whole system is continuity water supply.

High filtration precision: the filtration precision can be up to 20 microns, with a variety of precision filter screens.

Large filtration area: the standard effective filtration area is larger 7 to 40 times than the entrance area.

Reliable cleaning: there are a variety of control modes, such as manual, pressure difference , time, setting and PLC program logic control .

Low-cost and simple installation: various structure forms, suitable for installation various of conditions.

Long service life: more than 10 years ; the filter screen is made of stainless steel, and if necessary, the filter screens of different specifications can easily be replaced.

Important parts for filtration system:

01. Carbon steel cycloner,

02. Stainless screen,

03. Butterfly valve

04. Sewage device, etc.

Technical Parameters:

| Model | Flow (T/h) | Inlet and outlet diameter (mm) | Drainage diameter (mm) | D (mm) | H (mm) | H1 (mm) | H2 (mm) |

| YLF-50 | 70 | DN50 | DN50 | 300 | 1690 | 265 | 640 |

| YLF-80 | 80 | DN80 | DN50 | 350 | 1720 | 265 | 660 |

| YLF-100 | 120 | DN100 | DN50 | 400 | 1760 | 265 | 680 |

| YLF-200 | 200 | DN200 | DN80 | 500 | 1860 | 290 | 715 |

| YLF-250 | 280 | DN250 | DN80 | 600 | 1930 | 290 | 755 |

| YLF-300 | 450 | DN300 | DN100 | 700 | 2040 | 335 | 755 |

| YLF-350 | 600 | DN350 | DN100 | 800 | 2105 | 335 | 770 |

| YLF-400 | 800 | DN400 | DN100 | 1000 | 2220 | 335 | 800 |

| YLF-500 | 1000 | DN500 | DN100 | 1200 | 2360 | 365 | 825 |

Product Categories : Water Filter > Automatic Backwash Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)