200 Mircon Online Baclwashing/ Self-Cleaning Stainless Steel Water Strainer

Basic Info

Model No.: YLF-250

Product Description

Model NO.: YLF-250 Usage: Environmental Protection, Chemical Industry, Water Treatment Style: Vertical Certification: CE, SGS Working Pressure: Less Than 1.0 MPa Pressure Loss: Less Than 0.015MPa Interface: Flange Inlet and Outlet Diameter: 10 Inch Trademark: YLD Origin: Jiangyin, Jiangsu Type: Self-Cleaning and Automatic Backwash Motive Force: Electric power Performance: Efficient Filtration Material: Carbon Steel/Stainless Steel Working Temperature: Less Than 100centigrade Filtering Precision: 100-3000 Micron Flow Rate: 280 M3/H Drian: 3 Inch Specification: CE, SGS HS Code: 8421219990 200 Mircon Online Baclwashing/ Self-cleaning Stainless Steel Water Strainer

Design feature of the multi— Core self— Cleaning filter

1. The filter takes the internal mechanical structure of self-cleaning to realize the backwashing function in the true sense. It could clean the impurity on the strainer thoroughly. There is no dead angle for washing and no flux attenuation so that the filtering efficiency and the service life are assured.

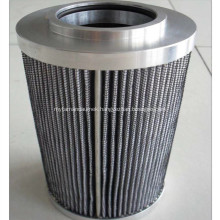

2. The filter takes the wedge strainer of 304, 316L stainless steel with high strength, precision and corrosion resistance. The filtering precision is 251im.

3. The filter with few wearing parts, no consumable, low maintenance cost. The operation and management are simple.

4. The control system of the filter is with sensitive response and precise operation. The backwashing pressure difference and the time could be adjusted flexibly according to the different water source and filtering precision.

Introduction

Self clean filter has metal filter cartridges inside. When filter elements clogged, a specially designed back-flushing arm will clean the elements one by one. When filtering, the water enters the element from both ends. When self-cleaning, the top end partly opens and the water flushed out of the bottom end.

Self clean filter has very large filter area, high flowrate, compact structure and high reliability and works better for high flowrate and dirty water filtration applications. self clean filter has tow sub-series: M Series, for the low flowrate or filtration at rating > 300 μm. S Series, for the filtration at rating < 300 μm. Single filter flowrate range is 5~3000 m3/h. The inlet and outlet nozzle range is 2"~24".

Self clean filter is capable to remove the solid particles from water and low viscosity liquid (metal working coolant for example). Filter makes the fluid meet the cleanness requirement and protects the downstream key equipment from clogging, abrasing and fouling. It increases the key equipment running efficiency and service life. Series self clean filter automatically works continuously on-line; it reduces the downtime cost, maintenance cost and labor cost. Series self clean filter is an ideal solution for water and low viscous liquid self-cleaning filtration.

Working Principle

[ Filtering ] Liquid flows into the filter via the inlet, part of liquid flows directly through filter elements from the lower ends; another part of liquid flows through the distribution pipe and into the upper part of the filter and then flows into the filter elements from the upper and lower ends at the same time,and then flows through the internal surface of filter element and goes out from the outlet. Impurities are intercepted by the elements and the filter cake slowly accumulates, which leads to gradually pressure drop increasing between the inlet and outlet. It indicates that the filter cake reaches certain thickness,and the flux of filter element becomes lower

[ Back-flushing ] When the preset pressure drop or time exceeds, the self-cleaning program is triggered. The gear motor drives the cleaning arm to aim at one element to partly cap the upper end of the element and connect its lower end to the cleaning nozzle. And then the cleaning valve opens and connect the element and discharging pipe. the differential pressure between the element's outside and discharging nozzle will make the filtrate back-flush the filter element, filter cake dislodged and be purged downward into the sewage pipe. After one element cleaned, the cleaning valve closes and the cleaning arm aims at the next one. When all filter elements cleaned, the entire back-flushing sequences are completed.

FAQ:

01. What is the capacity (m3/hour)you required for this equipment?

02. What is the material for this filter?

Carbon steel ?or stainless steel (SS304/SS316)?

03. What is the filtration degree?

10 micron or 200 micron?

04. What is the power supply in your country?

220V/60Hz or other? Contact us if you need more details on Water Treatment Equipment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Filter System、Industrial Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Design feature of the multi— Core self— Cleaning filter

1. The filter takes the internal mechanical structure of self-cleaning to realize the backwashing function in the true sense. It could clean the impurity on the strainer thoroughly. There is no dead angle for washing and no flux attenuation so that the filtering efficiency and the service life are assured.

2. The filter takes the wedge strainer of 304, 316L stainless steel with high strength, precision and corrosion resistance. The filtering precision is 251im.

3. The filter with few wearing parts, no consumable, low maintenance cost. The operation and management are simple.

4. The control system of the filter is with sensitive response and precise operation. The backwashing pressure difference and the time could be adjusted flexibly according to the different water source and filtering precision.

Introduction

Self clean filter has metal filter cartridges inside. When filter elements clogged, a specially designed back-flushing arm will clean the elements one by one. When filtering, the water enters the element from both ends. When self-cleaning, the top end partly opens and the water flushed out of the bottom end.

Self clean filter has very large filter area, high flowrate, compact structure and high reliability and works better for high flowrate and dirty water filtration applications. self clean filter has tow sub-series: M Series, for the low flowrate or filtration at rating > 300 μm. S Series, for the filtration at rating < 300 μm. Single filter flowrate range is 5~3000 m3/h. The inlet and outlet nozzle range is 2"~24".

Self clean filter is capable to remove the solid particles from water and low viscosity liquid (metal working coolant for example). Filter makes the fluid meet the cleanness requirement and protects the downstream key equipment from clogging, abrasing and fouling. It increases the key equipment running efficiency and service life. Series self clean filter automatically works continuously on-line; it reduces the downtime cost, maintenance cost and labor cost. Series self clean filter is an ideal solution for water and low viscous liquid self-cleaning filtration.

Working Principle

[ Filtering ] Liquid flows into the filter via the inlet, part of liquid flows directly through filter elements from the lower ends; another part of liquid flows through the distribution pipe and into the upper part of the filter and then flows into the filter elements from the upper and lower ends at the same time,and then flows through the internal surface of filter element and goes out from the outlet. Impurities are intercepted by the elements and the filter cake slowly accumulates, which leads to gradually pressure drop increasing between the inlet and outlet. It indicates that the filter cake reaches certain thickness,and the flux of filter element becomes lower

[ Back-flushing ] When the preset pressure drop or time exceeds, the self-cleaning program is triggered. The gear motor drives the cleaning arm to aim at one element to partly cap the upper end of the element and connect its lower end to the cleaning nozzle. And then the cleaning valve opens and connect the element and discharging pipe. the differential pressure between the element's outside and discharging nozzle will make the filtrate back-flush the filter element, filter cake dislodged and be purged downward into the sewage pipe. After one element cleaned, the cleaning valve closes and the cleaning arm aims at the next one. When all filter elements cleaned, the entire back-flushing sequences are completed.

| Model | Flow (T/h) | Inlet and outlet diameter (mm) | Drainage diameter (mm) | D (mm) | H (mm) | H1 (mm) | H2 (mm) |

| YLF-50 | 70 | DN50 | DN50 | 300 | 1690 | 265 | 640 |

| YLF-80 | 80 | DN80 | DN50 | 350 | 1720 | 265 | 660 |

| YLF-100 | 120 | DN100 | DN50 | 400 | 1760 | 265 | 680 |

| YLF-200 | 200 | DN200 | DN80 | 500 | 1860 | 290 | 715 |

| YLF-250 | 280 | DN250 | DN80 | 600 | 1930 | 290 | 755 |

| YLF-300 | 450 | DN300 | DN100 | 700 | 2040 | 335 | 755 |

| YLF-350 | 600 | DN350 | DN100 | 800 | 2105 | 335 | 770 |

| YLF-400 | 800 | DN400 | DN100 | 1000 | 2220 | 335 | 800 |

| YLF-500 | 1000 | DN500 | DN100 | 1200 | 2360 | 365 | 825 |

FAQ:

01. What is the capacity (m3/hour)you required for this equipment?

02. What is the material for this filter?

Carbon steel ?or stainless steel (SS304/SS316)?

03. What is the filtration degree?

10 micron or 200 micron?

04. What is the power supply in your country?

220V/60Hz or other? Contact us if you need more details on Water Treatment Equipment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Filter System、Industrial Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Filter > Automatic Backwash Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)