Basic Solids Removal Self Cleaning Screen Filters

Basic Info

Model No.: YL-8V

Product Description

Model NO.: YL-8V

Usage: Environmental Protection

Style: Vertical

Certification: CE, GS

Design Pressure: 1.6MPa,1.0MPa

Filtering Screen: Ss304/Ss316,316L

Control System: Timer Controller,PLC

Cleaning Shaft: Ss304/316

Trademark: YLD

Origin: Jiangyin, China

Type: Water Filter

Motive Force: Electric power

Performance: Efficient Filtration

Material for Filter Housing: Carbon Steel,Stainless Steel304/316,etc

Working Pressure: No Less Than 0.6MPa

Filtration Micron: 150-2000 Micros

Working Temperature: No More Than 90 Centigrade

Double Clean Brush: Option

Specification: to be practical

HS Code: 842121999

Why spend hundreds of dollars month after month on maintenance for your industrial water application when an Automatic Self Cleaning Filter can eliminate the manual effort in your process?

Our Automatic Self Cleaning Filters are designed to to meet pressure, gallons per minute, and temperature requirements from a wide variety of water sources. Click the get a quote button to have a filtration specialist tell you more.

Cooling Towers: Can be integrated at any point within a process cooling system.

Petrochemical: Self-cleaning water filters ensure that continuous water flow.

Seawater: Industrial water filters provide a vital tool for solid removal from seawater.

Food Processing: Regulate water quality to ensure cleanliness and proper hygiene.

Water Processing: These filters provide reliable and efficient particle removal.

Irrigation: Eliminate debris from clogging lines, while improving overall water quality.

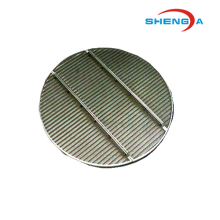

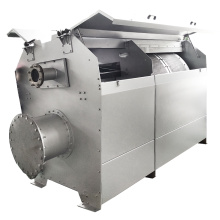

Automatic Screen Filter

A series of heavy duty filters with automatic cleaning, designed for filtrates with high content of suspended solids and high flow rates. When a differential pressure is sensed the cleaning cycle is initiated and two stainless steel brushes remove debris from the filter screen. The debris is then flushed out the exhaust, using less than 1% of the total flow and without interrupting output. Filtration degrees between 200-3500 micron and flow rates of up to 7200 m3/s can be achieved. Higher flow rates can be achieved by banking multiple units.

The cleaning process

During filtration water flows though the cylindrical screen of the strainer from the inside out. Debris collected on the inner surface of the screen form a "filter cake" that causes a pressure drop across the screen. When this pressure differential reaches a preset value, it is detected by the filter control system and the self-cleaning process automatically starts.

A specially designed exhaust valve, opens and the drive unit starts to rotate two stainless steel brushes which sweep the inner surface of the cylindrical screen. The particles trapped on the screen are dislodged by the revolving brushes and flushed out through the open exhaust valve. Service flow of filtered water is uninterrupted throughout the approximate 20 seconds cleaning process. At the end of the self-cleaning process the motor stops and the exhaust valve closes. The filter control system continues to monitor the differential pressure and when needed starts a new self-cleaning cycle. automatic brush filters are useful mostly for heavy duty, heavy dirt load and coarse filtration applications ranging from 3500 to 200 micron.

Function

Automatic Brush Filter the original water filtration and automatic filter cleaning discharge function, and cleaning sewage system uninterrupted water supply. Automatic Brush Filter cleaning has two control modes: Automatic control and manual control.

Automatic control: Automatic control timing and pressure difference. In the filtering time timer is set on the filtration time, when the filtering time, start the sewage, discharge time from emission time timer setting. At the same time control system real time system and the pressure difference of the user set pressure difference comparison, when the system pressure reaches the set pressure, Also for cleaning sewage filter, pollution by sewage time timer. Arrive at discharge sewage time, stop washing, the system is restored to its initial state, following is the preparing for the next process.

Manual control: Will the operation panel on the automatic / manual selection switch to manual position, filter for sewage.

The user can choose according to the two control mode, specific operations, see behind the operation part.

| Advantages |

| No chemicals |

| No polymers |

| A bare minimum of back flush water |

| Small footprint saves valuable space |

| Low maintenance |

| Fast Return On Investment |

| Assists water conservation |

Scope of application:

The circulated or non-circulated cooling water system, heat exchange system, central air conditioning system and central heating system in the industries like architecture, chemistry, metallurgy, rubber, paper making, light textile, coal and foods, used to protect the cooling equipment, heat exchange device and air conditioner accordingly.

| model | water inlet-outlet | housing diameter | capacity | weight | |

| inch | mm | mm | m3/hour | Kg | |

| YL-2V | 2 | 50 | 159 | 19 | 80 |

| Y-2.5V | 2.5 | 65 | 159 | 28 | 100 |

| YL-3V | 3 | 80 | 219 | 50 | 130 |

| YL-4V | 4 | 100 | 219 | 80 | 170 |

| YL-5V | 5 | 125 | 219 | 125 | 200 |

| YL-6V | 6 | 150 | 273 | 180 | 270 |

| YL-8V | 8 | 200 | 325 | 320 | 350 |

| YL-10V | 10 | 250 | 377 | 490 | 390 |

| YL-12V | 12 | 300 | 426 | 710 | 480 |

| YL-14V | 14 | 350 | 478 | 970 | 550 |

Contact us if you need more details on Brush Clean Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Brush Filter、Screen Brush Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Filter > Automatic Self Cleaning Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)