90% Better Efficiency Hydrocyclone Separates Sand Filter From Water

Basic Info

Model No.: YLXC-125II

Product Description

Model NO.: YLXC-125II

Usage: Environmental Protection, Water Treatment

Style: Vertical

Certification: CE, SGS

Working Principle: Centifugal

Control System: Manual,Automatic Drain

Working Pressure: 0.2-0.5MPa

Working Temperature: Ambient

Filter Screen: Option

Specification: to be practical

HS Code: 842121999

Type: Cyclone

Motive Force: Pressure

Performance: Cyclone Filter

Material for Housing: Carbon Steel,Ss

Structure: Round/Conic Housing

Desanding Efficiency: .99%

Sand Particles: >0.1mm

Water Head Loss: <0.02MPa

Trademark: YLD

Origin: Jiangyin, China

90% Better Efficiency Hydrocyclone Separates Sand From Water

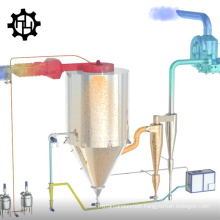

How the Hydrocyclone Separates Sand work?

In a cyclone separator, dirty flue gas is fed into a chamber. Inside this chamber exists a spiral vortex, similar to a tornado. This spiral formation and the separation is shown in Figure 2. The lighter components of this gas have less inertia, so it is easier for them to be influenced by the vortex and travel up it. Unlike these particles, larger components of particulate matter have more inertia and are not as easily influenced by the vortex

Because these larger particles have difficulty following the high-speed spiral motion of the gas and the vortex, the particles hit the inside walls of the container and drop down into a collection hopper. These chambers are shaped like an upside-down cone to promote the collection of these particles at the bottom of the container. The cleaned flue gas escapes out the top of the chamber.

Most cyclones are built to control and remove particulate matter than is larger than 10 micrometers in diameter. However, there do exist high efficiency cyclones that are designed to be effective on particles as small as 2.5 micrometers. As well, these separators are not effective on extremely large particulate matter. For particulates around 200 micrometers in size,gravity settling chambers or momentum separators are a better option.

Out of all of the particulate-control devices, cyclone separators are among the least expensive. They are often used as a pre-treatment before the flue gas enters more effective pollution control devices. Because of this, cyclone separators can be seen as "rough separators" before they reach the fine filtration stages

Effectiveness

Hydrocyclone Separates Sand are generally able to remove somewhere between 50-99% of all particulate matter in flue gas.How well the cyclone separators are actually able to remove this matter depends largely on particle size. If there is a large amount of lighter particulate matter, less of these particles are able to be separated out. Because of this, cyclone separators work best on flue gases that contain large amounts of big particulate matter.

There are several advantages and disadvantages in using cyclone separators. First, cyclone separators are beneficial because they are not expensive to install or maintain, and they have no moving parts. This keeps maintenance and operating costs low. As well, the removed particulate matter is collected when dry, which makes it easier to dispose of. Finally, these units take up very little space. Although effective, there are also disadvantages in using cyclone separators. Mainly, the standard models are not able to collect particulate matter that is smaller than 10 micrometers effectively and the machines are unable to handle sticky or tacky material well.

FAQ:

01. What is the capacity (m3/hour)you required for this equipment?

02. What is the material for this cyclone filter?

Carbon steel ?or stainless steel (SS304/SS316)?

03. What is the power supply in your country?

220V/60Hz or other?

Techanical parameters sheet

| model | Capacity (m³/h) | Input pressure(Mpa) | Max partition diameter(mm) | partition size(um) | Desanding efficiency | dimension (mm) | Water Inlet (mm) | Water outlet (mm) | Sewage outfall (mm) | Weight (kg) | ||

| | | | | | | H1 | L | H2 | | | | |

| YLXC-25II | 18 | 0.15-0.4 | 1.5 | 30-70 | >96% | 850 | 273 | 1100 | 25 | 25 | 25 | 40 |

| YLXC-40II | 25 | 0.15-0.4 | 2 | 40-100 | >96% | 1050 | 273 | 1250 | 40 | 40 | 25 | 50 |

| YLXC-50II | 40 | 0.15-0.4 | 3 | 40-100 | >96% | 1100 | 273 | 1360 | 50 | 50 | 25 | 60 |

| YLXC-80II | 60 | 0.15-0.4 | 3 | 40-100 | >96% | 1150 | 273 | 1410 | 80 | 80 | 40 | 120 |

| YLXC-100II | 100 | 0.15-0.4 | 6 | 50-150 | >95% | 1200 | 325 | 1450 | 100 | 100 | 40 | 130 |

| YLXC-125II | 160 | 0.15-0.4 | 10 | 74-200 | >95% | 1250 | 377 | 1500 | 125 | 125 | 50 | 180 |

| YLXC-150II | 200 | 0.15-0.4 | 10 | 74-200 | >92% | 1350 | 426 | 1600 | 150 | 150 | 50 | 240 |

| YLXC-200II | 250 | 0.15-0.4 | 16 | 74-220 | >92% | 1450 | 530 | 1700 | 200 | 200 | 65 | 350 |

| YLXC-250II | 300 | 0.15-0.4 | 16 | 80-230 | >92% | 1550 | 630 | 1800 | 250 | 250 | 65 | 400 |

Contact us if you need more details on Water Treatment Equipment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Filter、Filter Housing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Cyclone Sand Separator

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)