Ss Screen Ball Collector Condenser Tube Cleaning Device

Basic Info

Model No.: YL-JC-600

Product Description

Model NO.: YL-JC-600 Usage: Environmental Protection Style: Vertical Certification: CE, GS Ball Collector: Carbon Steel Shell,Ss Filter Screen Cleaning Type: Rubber Ball Automatic Cleaning Working Pressure: 0.2-1.6MPa Control: Automatic Cleaning,Manual Timely Specification: to be practical HS Code: 842121999 Type: Condenser Cleaning Device Motive Force: Electric power Performance: Tube Cleaning Device Ball Pitcher: Carbon Steel,Ss Mesh Screen of Ball Collector: 1000 Micron-5000 Micron Power Supply: 200--1000W Cleaning Ball: Rubber,Ss Trademark: YLD Origin: Jiangyin, China

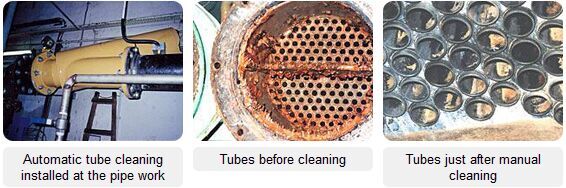

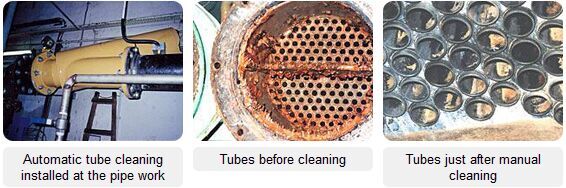

Condenser rubber ball cleaning device

For central air conditioning condenser and evaporator pipe, it is easy to be scaling. The normal daily Water Treatment should be processed during the summer time cooling water supply period,otherwise, the condenser will run in the high degree hardness water system,inorganic salts dissolved in circulating cooling water system will be crystallized and precipitated out ,scales will be formed on the tubes of condenserand it will reduce heat exchange efficiency. as hard scale increased, energy-consumption will be increased, when the knot hard mass scale is 1mm in thickness,the energy cost will be increased by 6%~10%; as water form scales with dirt, sediment, and rot colonization dirt, also the bacteria, and algae, microbial and its secretion form bio stick mud, it will attach in the pipes of condensation device, seriously it will caused pipeline block.Dirt and mud will effect hot exchange efficiency, higher energy cost will lead to high power voltage, seriously it cause super pressure voltage tilldowntime. Allthese factors affect the normal operation of the heat exchanger.

Condenser Tube Cleaning Device

Condenser and Concrete tube scaling is one of the most underestimated problems in the industry. It results in decrease of productivity and efficiency of the plant. We handle the two major methods used to fight the scaling. We provide online Condenser Tube Cleaning Systems (CTCS) along with Condenser Cleaning Sponge Balls made from Food Grade-A natural rubber to clean out the scaling. Furthermore, we also provide Offline Bullet Cleaning with our own skilled labor, machines and bronze bullets which can be performed during overhaul and shutdown. For the purpose of tackling similar problems with the Concrete Industry we have our Vulcan Clean-out Balls also made from Food Grade-A natural rubber.

Condenser cleaning ball

To furnish the diverse requirements of our clients we are involved in offering a wide range of Condenser Cleaning Ball. These are widely used for online cleaning of Power Plant Condensers in an efficient manner. We offer these in various specifications as per the requirements of our clients. Additionally, these can be availed at market leading prices.

We provide online Condenser Tube Cleaning Systems (CTCS) Along with Condenser Cleaning Sponge Balls made from Food Grade-A natural rubber to clean out the scaling. Please feel free for any requirements.

Some of the Key benefits of such a system are;

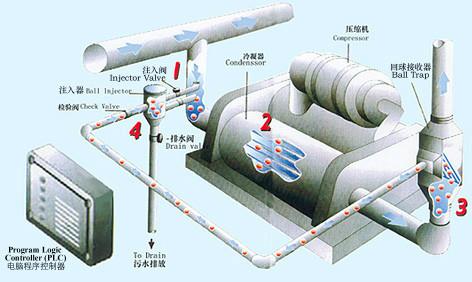

1. The system is completely automatic and there is no need of any chemical.

2. The system can work with any size heat exchanger or condenser.

3. The system can work with straight tube or "U" shape tubes.

4. The system can work with as many tubes as there are in the heat exchanger/condenser.

5. The system injecting point is installed on the heat exchanger/condenser inlet pipe, while the system balls trap is installed on the heat exchanger/condenser, outlet pipe.

6. The injecting cycle period and times per day, of the balls, is determinate by electronic controller.

7. The system use basic 220V/16A electric connection. In big systems, if needed, 3 phases are used.

8. The changing of the balls depends on few elements, such as the tubes material, the tubes condition, the liquid type, etc. In basic, the balls need to be changed at least once a year.

9. There is no need to put the same number of balls as the number of the tubes. Usually only 40% of balls are used.

10. It is important to have pressure deferent between the heat exchanger/condenser, inlet and outlet. The pressure deferent need to be at least 0.4 - 0.5 bar and or, at least flow of 1.3 - 1.5 m/s.

11. There is no special maintenance for the system. A once a day simple eye check, is enough. Once a year the system need to be examined by authorized Vulcan Industries representative.

12. The systems have 3 - 5 years guarantee for all the system parts. The client can also purchase extended guarantee for up to 30 years.13. System pay-back time, between 3 - 12 month.

Characteristics of condenser online cleaning device

1.energy saving,Min 10% and Max 40% ,99%rubber ball could be collected.

2, one-time investment cost could be recovered within one year.

3, automatic on-line cleaning to ensure without fouling, corrosion on the condenser.

4, avoid and eliminate air conditioner engine from abnormal pressure during operation.

5, prolong the service lifespan of compressor and the pipeline.

6, ensure the condenser to be in high heat transfer efficiency.

7,complete physical processing, cost- saving in chemical treatment, environmental protection.

8, full PLC computer programming control, no technicians maintainenance and regulates the frequency of automatic cleaning condenser every day.

Technical parameters

1. Performance: ball collecting rate ≤95%

2. Input voltage: 380V / 50HZ

3. Power: ≤5KW

4. Work environment requirements: Temperature ≤55 ºC, humidity ≤95 ºCRelative

5. Pressure loss: 0.003MPa-0.05MPa

6. Water temperature: ≤50 ºC

7. Working Pressure: ≤1.6MPa.

Contact us if you need more details on Condenser Cleaning System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tube Cleaning Device、Condenser Tube Cleaning. If these products fail to match your need, please contact us and we would like to provide relevant information.

Condenser rubber ball cleaning device

For central air conditioning condenser and evaporator pipe, it is easy to be scaling. The normal daily Water Treatment should be processed during the summer time cooling water supply period,otherwise, the condenser will run in the high degree hardness water system,inorganic salts dissolved in circulating cooling water system will be crystallized and precipitated out ,scales will be formed on the tubes of condenserand it will reduce heat exchange efficiency. as hard scale increased, energy-consumption will be increased, when the knot hard mass scale is 1mm in thickness,the energy cost will be increased by 6%~10%; as water form scales with dirt, sediment, and rot colonization dirt, also the bacteria, and algae, microbial and its secretion form bio stick mud, it will attach in the pipes of condensation device, seriously it will caused pipeline block.Dirt and mud will effect hot exchange efficiency, higher energy cost will lead to high power voltage, seriously it cause super pressure voltage tilldowntime. Allthese factors affect the normal operation of the heat exchanger.

Condenser Tube Cleaning Device

Condenser and Concrete tube scaling is one of the most underestimated problems in the industry. It results in decrease of productivity and efficiency of the plant. We handle the two major methods used to fight the scaling. We provide online Condenser Tube Cleaning Systems (CTCS) along with Condenser Cleaning Sponge Balls made from Food Grade-A natural rubber to clean out the scaling. Furthermore, we also provide Offline Bullet Cleaning with our own skilled labor, machines and bronze bullets which can be performed during overhaul and shutdown. For the purpose of tackling similar problems with the Concrete Industry we have our Vulcan Clean-out Balls also made from Food Grade-A natural rubber.

Condenser cleaning ball

To furnish the diverse requirements of our clients we are involved in offering a wide range of Condenser Cleaning Ball. These are widely used for online cleaning of Power Plant Condensers in an efficient manner. We offer these in various specifications as per the requirements of our clients. Additionally, these can be availed at market leading prices.

We provide online Condenser Tube Cleaning Systems (CTCS) Along with Condenser Cleaning Sponge Balls made from Food Grade-A natural rubber to clean out the scaling. Please feel free for any requirements.

Some of the Key benefits of such a system are;

1. The system is completely automatic and there is no need of any chemical.

2. The system can work with any size heat exchanger or condenser.

3. The system can work with straight tube or "U" shape tubes.

4. The system can work with as many tubes as there are in the heat exchanger/condenser.

5. The system injecting point is installed on the heat exchanger/condenser inlet pipe, while the system balls trap is installed on the heat exchanger/condenser, outlet pipe.

6. The injecting cycle period and times per day, of the balls, is determinate by electronic controller.

7. The system use basic 220V/16A electric connection. In big systems, if needed, 3 phases are used.

8. The changing of the balls depends on few elements, such as the tubes material, the tubes condition, the liquid type, etc. In basic, the balls need to be changed at least once a year.

9. There is no need to put the same number of balls as the number of the tubes. Usually only 40% of balls are used.

10. It is important to have pressure deferent between the heat exchanger/condenser, inlet and outlet. The pressure deferent need to be at least 0.4 - 0.5 bar and or, at least flow of 1.3 - 1.5 m/s.

11. There is no special maintenance for the system. A once a day simple eye check, is enough. Once a year the system need to be examined by authorized Vulcan Industries representative.

12. The systems have 3 - 5 years guarantee for all the system parts. The client can also purchase extended guarantee for up to 30 years.13. System pay-back time, between 3 - 12 month.

Characteristics of condenser online cleaning device

1.energy saving,Min 10% and Max 40% ,99%rubber ball could be collected.

2, one-time investment cost could be recovered within one year.

3, automatic on-line cleaning to ensure without fouling, corrosion on the condenser.

4, avoid and eliminate air conditioner engine from abnormal pressure during operation.

5, prolong the service lifespan of compressor and the pipeline.

6, ensure the condenser to be in high heat transfer efficiency.

7,complete physical processing, cost- saving in chemical treatment, environmental protection.

8, full PLC computer programming control, no technicians maintainenance and regulates the frequency of automatic cleaning condenser every day.

Technical parameters

1. Performance: ball collecting rate ≤95%

2. Input voltage: 380V / 50HZ

3. Power: ≤5KW

4. Work environment requirements: Temperature ≤55 ºC, humidity ≤95 ºCRelative

5. Pressure loss: 0.003MPa-0.05MPa

6. Water temperature: ≤50 ºC

7. Working Pressure: ≤1.6MPa.

Contact us if you need more details on Condenser Cleaning System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tube Cleaning Device、Condenser Tube Cleaning. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Condenser Cleaning Device

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)