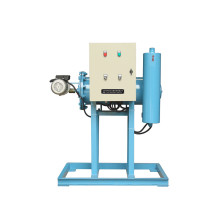

Side Stream Water Treatment Equipment for Cooling Water System

Basic Info

Model No.: YL-II-10G

Product Description

Model NO.: YL-II-10G

Motive Force: Electric power

Input Supplying: 220V, 50Hz

Working Voltage: Less Than36V

Corrosive Rate: More Than97%

The Loss of Water Head: 0.2 to 1.0m

Removal and Prevent in Scale: More Than99%

Specification: CE, GSG

HS Code: 8421219990

Usage: Chemical Industry

Certification: CE

Sterilization Efficiency: More Than99%

Raw Water Temperature: 0 to 95 Centigrade

Qualified Water Quality: Reach The National Standard

Total Hardness: Less Than700mg/L

Trademark: YLD

Origin: Jiangyin, Jiangsu, China

Product Introduction

By-pass flow water processor is a new product developed on the basis of full-flow water processor, with the principle of overlapped low-voltage pulsed electric field, which can automatically adjust output signals depending on water quality. After treatment with water processor, the density water of molecule is decreased and its structure is also changed, for example, longer dipole moment of water molecule, higher polarity and larger surface tension, so that water molecule can be used for scale dissolution and further for scale removal.

Electrodes may act on the processor and the processor will generate a large number of small crystals with the function of scale prevention. These crystals can remove ions easy to form scale by chemical reaction, form loose aragonite crystals after reaction, and finally automatically be discharged through drain valve. Dissolved oxygen of water being treated by the processor will be activated. Electrolyzed by electrodes, water will be decomposed into OW, 02, H202 and a large number of reactive oxygen species which are featured with strong oxidizing properties and can thoroughly kill microorganisms and various algae. As a result, bacteria and algae can be removed and scale can be prevented.

Meanwhile, the pipe wall of system will be further oxidized by a mass of active oxygen generated by the processor and a dense oxidation film will be formed, such as ferroferric oxide. The oxidation film can make the pipe wall passivated, prevent pipeline corruption, increase the service life of system and further prevent equipment corruption.

Product Features

Only consume 1%- 3% of the water system flow should be treated by by- Pass flow water processor with easy installation.

Legionella will be killed by strong pulsed electric field.

No need of any chemicals, without generation of second pollution, environmental protection

Rust and yellow water removal

Turbidity reduction

Obvious effects

Features

Kill bacteria in the water

Inhibit algae

Anti equipment pipeline corrosion

Kill the Legionella

Waterproof scale, descale

Remove suspended solids

Applicable Scope

Central air conditioning cooling, chilled water system

Refrigeration cycle water system

Industrial cooling water circulation system

Heat exchange systems and cooling tower system

System properties

Open cooling water circulating system

Closed circulating water system

1

By-pass flow water processor (side stream treatment equipment)

As there are differences between open cooling water system and closed circulating water system (as shown in the table below), it is necessary to adopt different water processors for Water Treatment based on their own features.

System water is open, so that heat will be released to the air by means of water evaporation.

System water is closed, used for heat delivery.

Not concentrated

Weak

Slow

No

Water is concentrated or not Concentrated

Trend of water scale Strong

Growth of bacteria Fast

Growth of algae Yes

Based on the drift diameter of header pipe, F-type water processor is suitable for open cooling water system, that is, applicable drift diameter of the water processor is the same as that of the header pipe of the system.

Based on the drift diameter of header pipe, G-type water processor is suitable for closed cooling water system, that is, applicable drift diameter of the water processor is the same as that of the header pipe of the system

| Type | Dimension | Detailed dimension | Connecting pipe | The loss of water head (mm) | Power less than (w) | Weight (Kg) | ||||||

| Model | Pipe dimension (mm) | L (mm) | W (mm) | H (mm) | A (mm) | B (mm) | C (mm) | Inlet and outlet diameter (mm) | Outfalldrift diameter(mm) | |||

| YLD-II-1G | 80 | 900 | 560 | 1200 | 500 | 350 | 120 | 25* | 25 | 0.2 | 50 | 100 |

| YLD-II-2G | 100 | 900 | 560 | 1200 | 500 | 350 | 120 | 25* | 25 | 0.4 | 90 | 100 |

| YLD-II-3G | 150 | 900 | 560 | 1200 | 500 | 350 | 120 | 25* | 25 | 0.7 | 120 | 102 |

| YLD-II-4G | 200 | 900 | 560 | 1200 | 500 | 350 | 120 | 25* | 25 | 1.0 | 160 | 110 |

| YLD-II-5G | 250 | 900 | 560 | 1200 | 500 | 350 | 120 | 25* | 25 | 1.0 | 220 | 110 |

| YLD-II-6G | 300 | 900 | 560 | 1200 | 500 | 350 | 120 | 32* | 25 | 1.0 | 300 | 115 |

| YLD-II-7G | 350 | 900 | 560 | 1200 | 500 | 350 | 120 | 32* | 25 | 1.0 | 500 | 120 |

| YLD-II-8G | 400 | 900 | 560 | 1200 | 500 | 350 | 120 | 40* | 25 | 1.0 | 600 | 130 |

| YLD-II-9G | 450 | 950 | 580 | 1200 | 500 | 350 | 120 | 40* | 25 | 1.0 | 800 | 160 |

| YLD-II-10G | 500 | 950 | 580 | 1200 | 500 | 350 | 120 | 50 | 25 | 1.0 | 900 | 180 |

| YLD-II-11G | 600 | 950 | 580 | 1200 | 500 | 350 | 120 | 50 | 25 | 1.0 | 1100 | 190 |

| YLD-II-12G | 700 | 1000 | 1100 | 1200 | 500 | 350 | 120 | 65 | 25 | 1.0 | 1400 | 236 |

| YLD-II-13G | 800 | 1000 | 1100 | 1200 | 500 | 350 | 120 | 65 | 25 | 1.0 | 1700 | 250 |

Contact us if you need more details on Water Descaling Equipment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about By-Pass Flow Water Processor、Anti-Scaling Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Descaling Equipment > Side Stream/By Pass Water Descaling Equipment

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)