UV Pool Sanitizer Ultraviolet Water Sterilizer UV Water Disinfection System

Basic Info

Model No.: YLC-500

Product Description

Model NO.: YLC-500 Application: Various Water System Disinfection Method: Ultraviolet Material: Stainless Steel Ss304, Ss316 Lifespan of UV Lamp: 9000-12000 Hours Flow Rate: 0.3--1000 Ton/Hour System Working Pressure Resistance: (0.6 Mpa)6kg/Cm2 Brand of Ballast: Beasun Specification: CE, SGS HS Code: 842121999 Certification: BV, ISO9001, SGS, CE Voltage: 220V Bactericidal Efficienc: 98% Kill Total Coliforms Medium Material: PP (Propene Polymer) Interface Type: Flange or Thread Alert System for Lamp: One Set Raw Water Supplying: Running Water Trademark: YLD Origin: Jiangyin, Jiangsu

UV Pool Sanitizer Ultraviolet Water Sterilizer UV water disinfection system

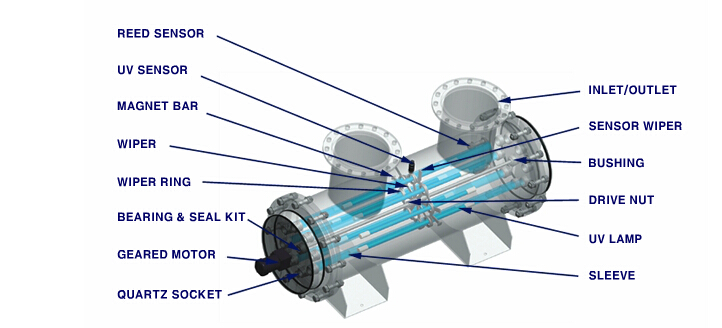

UV Systems Features & Benefits

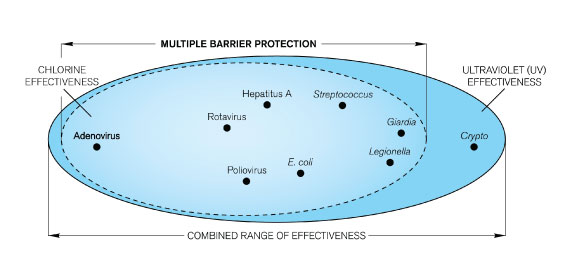

Provides water disinfection without the use of chemicals

Reduces bacteria, viruses, Microorganisms and protozoa by 99.99%

245 nm monitors to keep track of UV intensity and lapsed running time

Electronic ballasts provide constant output current over the entire operating range

Lamp "on" and audible lamp failure indicators

Annual lamp replacement reminder

Improved surge protection

Electro-polished 304 stainless steel reactor chambers for increased durability

Easy servicing (no need to disconnect water flow during lamp replacement)

Open end quarts sleeves for optimum operating temperature and sealing efficiency

Non-corrosive aluminum base for quick and easy servicing

How does the UV pool sanitizer work?

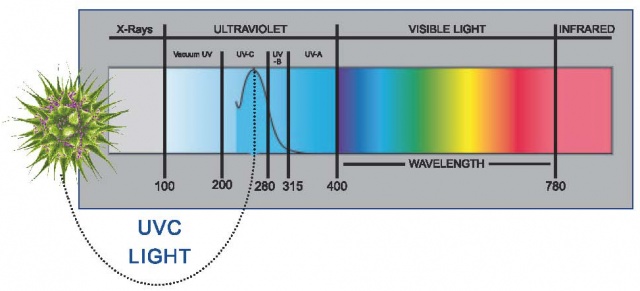

As pool water is circulated through the wet reactor chamber of the Ultra UV system, one or more UV-C germicidal lamps contained in the reactor(s) expose the pool water containing bacteria, viruses, algae spores, pathogens and microorganisms, to the high intensity light waves emitted by the UV-C lamp(s). This causes the DNA of these pathogens to be disrupted and unable to multiply. Without the ability to multiply, these pathogens die and are rendered harmless. It is easy to understand that bacteria laden water enters the reactor, and drinking quality water leaves the reactor back to the pool. Consult the Technical link for a more technical explanation of this process. (Note: While drinking quality water exits the Ultra UV pool sanitizer, it is not intended for use in sanitizing drinking water and should not be used as such. Drinking water sanitizers have different technical requirements (alarms, etc) then do swimming pool UV systems).

Application

* Water disinfection of food processing industry, including juices, milk, drinks, beer, practical oil, and all kinds of canned food, beverage products, such as water disinfection.

* Ultra-pure water for electronic industry.

* Hospitals, various laboratory water disinfection, and high levels of pathogenic body water disinfection.

* Water disinfection applications, including residents of households building, residential, office building, hotels, restaurants, water factory.

* Fish processing purification and disinfection, purification and disinfection of shellfish, fish cleaning and disinfection process.

* Military camp, field water supply system.

* Urban wastewater disinfection, the maximum capacity of up to 1 million tons or more per day.

* Swimming pool, other recreational water disinfection water.

* Cooling water disinfection, including thermal power, nuclear power plant cooling water, industrial cooling water, cooling water, central air conditioning system.

* Biological, chemical and pharmaceutical, cosmetics for the production of cooling water.

* Sea water, fresh water breeding, aquaculture (fish, eel, shrimp, abalone, shellfish, etc. ) water, the total treated water up to 200 thousand tons per day or more.

* Agricultural water disinfection, including greenhouse water use and irrigation.

Principle of Operation

UV water disinfection system design has been carefully conceived to provide adequate germicidal dosage throughout the disinfection chamber. The dosage, as it applies to UV disinfection, is a function of time and the intensity of UV radiation to which the water is exposed. Exposure time is related to the flow rate, the higher the flow rate, the lower the exposure time or the lower the flow rate, the higher the exposure time. The UV intensity is the amount of energy, per unit time, emitted by germicidal lamp. The Dosage is the product of UV intensity and the exposure time.

Limitation of Use

The UV water disinfection system NOT intended for the treatment of water that has an obvious contamination or intentional source, such as raw sewage, nor is the unit intended to convert wastewater to microbiologically safe drinking water.

Water Quality (in)

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels

Maximum Concentration Levels (Very Important)

Iron≤ 0.3ppm(0.3mg/L)

Hardness≤ 7gpg(120mg/L)

Turbidity≤ 1NTU

Manganese≤ 0.05ppm(0.05mg/L)

Tannins≤ 0.1ppm(0.3mg/L)

UV Transmittance≥ 750‰

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added measures to improve water quality to treatable levels. If, for any reason, it is believed the UV transmission is not satisfactory, contact the factory.

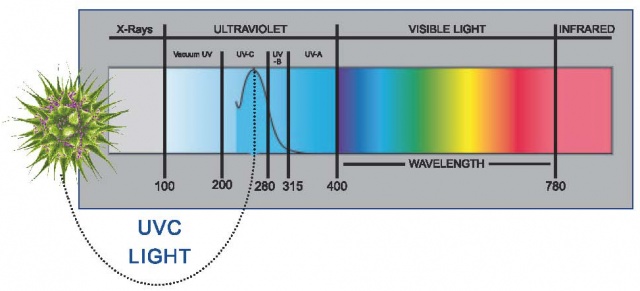

UV wavelength (nm)

DOSAGE is the product of intensity & time

Dosage=intensity*time=micro watt/cm2*time=microwatt-seconds per square centimeter

(μ W-s/cm2)

Note: 1000μ W-s/cm2=1mj/cm2(milli-joule/cm2)

As a general guideline, the following are some typical UV transmission rates (UVT)

City water supplies850-980‰

De-ionized or Reverse Osmosis water950-980‰

Surface waters(lakes, rivers, etc)700-900‰

Ground water(wells)900-950‰

Other liquids10-990‰

FAQ

Q. How does one properly size a UV system?

A. A UV system for a swimming pool is sized to match up with the water flow of the pool circulation pump(s). Consult the Ultra UV Owner's Manual to see which model Ultra UV system matches the flow rate of a specific circulation pump. Information accompanying the pump can provide this flow rate, as can the pump supplier's literature or website, or the dealer or installer that provided the pump. And, remember that the Ultra UV pool sanitizer is convertible to allow for increasing the killing power of the UV system if a system was selected originally that was undersized due to under estimating the pool's circulation pump output rate of flow.

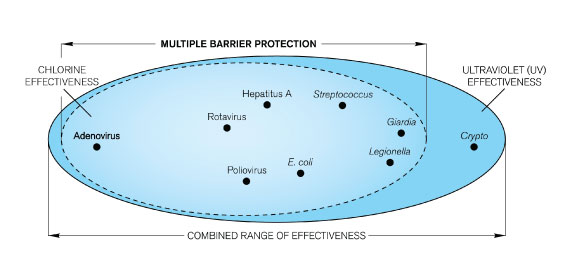

Q. Do I still need to use chemicals in the pool?

A. As noted in the first question and answer, the Ultra UV pool sanitizer treats the water as it passes through the reactor chamber of the system. When organic materials, such as skin scrapings, urine, sweat, bird droppings, dust etc. enter the pool, there must be a low level of sanitizer present to treat the pool water until it reaches the UV reactor. Owners of UV systems report sanitizing chemical reductions of 50%-70% in many cases. Chemicals for control of pH, and other chemicals the pool owner may have used prior to the installation of their UV system should still be followed, as the Ultra UV system imparts nothing into the pool water when killing bacteria in the pool water. This is a real plus over alternate sanitizing methods that add chemicals to the pool water during the sanitization process.

Q. If chlorine is used after UV installation, will the chlorine smell still be present?

A. One of the side benefits of the Ultra UV system is its ability to reduce or eliminate mono-chloramine in the pool water. Chloramines are the by-products of chlorination and are the "chlorine smelly" odor associated with chlorinated pools. With proper Ultra UV sizing and chemical maintenance, the chloramine "chlorine" odor can be eliminated and the pool returned to a safe and enjoyable environment.

Q. How is the UV system installed in the average pool?

A. The Ultra UV pool samitizer installs in the circulation system, after the filter and before any heater or chemical injection points. Designed to accommodate 3 different pump output flow rate ranges up to 130 GPM (40.4 m3/hr), installing the Ultra UV system is a simple and low cost procedure for the pool builder or homeowner.

Q. Is the system available in the electrical power used in my country?

A. All Ultra UV systems are available in either 120V/50/60 Hz or 230V/50/60Hz electrical power.. Note: Do not operate the Ultra UV system on any power not indicated on the silver service plate on the front of the unit. These systems are NOT dual voltage. Contact us if you need more details on UV Sterilizer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ultraviolet Sterilizer、UV Disinfector. If these products fail to match your need, please contact us and we would like to provide relevant information.

UV Pool Sanitizer Ultraviolet Water Sterilizer UV water disinfection system

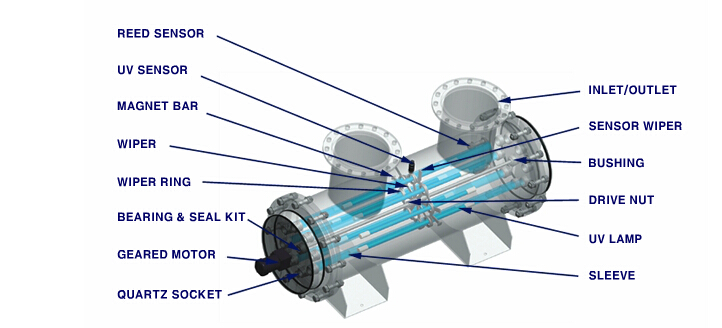

UV Systems Features & Benefits

Provides water disinfection without the use of chemicals

Reduces bacteria, viruses, Microorganisms and protozoa by 99.99%

245 nm monitors to keep track of UV intensity and lapsed running time

Electronic ballasts provide constant output current over the entire operating range

Lamp "on" and audible lamp failure indicators

Annual lamp replacement reminder

Improved surge protection

Electro-polished 304 stainless steel reactor chambers for increased durability

Easy servicing (no need to disconnect water flow during lamp replacement)

Open end quarts sleeves for optimum operating temperature and sealing efficiency

Non-corrosive aluminum base for quick and easy servicing

How does the UV pool sanitizer work?

As pool water is circulated through the wet reactor chamber of the Ultra UV system, one or more UV-C germicidal lamps contained in the reactor(s) expose the pool water containing bacteria, viruses, algae spores, pathogens and microorganisms, to the high intensity light waves emitted by the UV-C lamp(s). This causes the DNA of these pathogens to be disrupted and unable to multiply. Without the ability to multiply, these pathogens die and are rendered harmless. It is easy to understand that bacteria laden water enters the reactor, and drinking quality water leaves the reactor back to the pool. Consult the Technical link for a more technical explanation of this process. (Note: While drinking quality water exits the Ultra UV pool sanitizer, it is not intended for use in sanitizing drinking water and should not be used as such. Drinking water sanitizers have different technical requirements (alarms, etc) then do swimming pool UV systems).

Application

* Water disinfection of food processing industry, including juices, milk, drinks, beer, practical oil, and all kinds of canned food, beverage products, such as water disinfection.

* Ultra-pure water for electronic industry.

* Hospitals, various laboratory water disinfection, and high levels of pathogenic body water disinfection.

* Water disinfection applications, including residents of households building, residential, office building, hotels, restaurants, water factory.

* Fish processing purification and disinfection, purification and disinfection of shellfish, fish cleaning and disinfection process.

* Military camp, field water supply system.

* Urban wastewater disinfection, the maximum capacity of up to 1 million tons or more per day.

* Swimming pool, other recreational water disinfection water.

* Cooling water disinfection, including thermal power, nuclear power plant cooling water, industrial cooling water, cooling water, central air conditioning system.

* Biological, chemical and pharmaceutical, cosmetics for the production of cooling water.

* Sea water, fresh water breeding, aquaculture (fish, eel, shrimp, abalone, shellfish, etc. ) water, the total treated water up to 200 thousand tons per day or more.

* Agricultural water disinfection, including greenhouse water use and irrigation.

Principle of Operation

UV water disinfection system design has been carefully conceived to provide adequate germicidal dosage throughout the disinfection chamber. The dosage, as it applies to UV disinfection, is a function of time and the intensity of UV radiation to which the water is exposed. Exposure time is related to the flow rate, the higher the flow rate, the lower the exposure time or the lower the flow rate, the higher the exposure time. The UV intensity is the amount of energy, per unit time, emitted by germicidal lamp. The Dosage is the product of UV intensity and the exposure time.

Limitation of Use

The UV water disinfection system NOT intended for the treatment of water that has an obvious contamination or intentional source, such as raw sewage, nor is the unit intended to convert wastewater to microbiologically safe drinking water.

Water Quality (in)

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels

Maximum Concentration Levels (Very Important)

Iron≤ 0.3ppm(0.3mg/L)

Hardness≤ 7gpg(120mg/L)

Turbidity≤ 1NTU

Manganese≤ 0.05ppm(0.05mg/L)

Tannins≤ 0.1ppm(0.3mg/L)

UV Transmittance≥ 750‰

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added measures to improve water quality to treatable levels. If, for any reason, it is believed the UV transmission is not satisfactory, contact the factory.

UV wavelength (nm)

DOSAGE is the product of intensity & time

Dosage=intensity*time=micro watt/cm2*time=microwatt-seconds per square centimeter

(μ W-s/cm2)

Note: 1000μ W-s/cm2=1mj/cm2(milli-joule/cm2)

As a general guideline, the following are some typical UV transmission rates (UVT)

City water supplies850-980‰

De-ionized or Reverse Osmosis water950-980‰

Surface waters(lakes, rivers, etc)700-900‰

Ground water(wells)900-950‰

Other liquids10-990‰

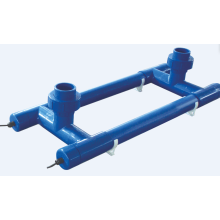

| model | Processing capacity (Ton/Hour) | power (W) | inlet and outlet (inch) | working pressure (Kg/cm 2 ) | malfunction alert for UV lamp | reactor dimension (cm) L×W×H | dimension of panel(cm) | anchor bolt (cm) | overall weight (Kg) |

| YLCn-005 | 0.3 | 16 | 1/2" | 6 | matched | 30×6×11 | 5 | ||

| YLCn-008 | 1 | 25 | 1/2" | 6 | matched | 47×6.3×11 | 10 | ||

| YLCn-050 | 2 | 40 | 1" | 6 | matched | 100×9×20 | Φ8.9×25 (diameter×length) | 69×4×Φ1 | 25 |

| YLCn-150 | 6 | 80 | 1+1/4" | 6 | matched | 100×11×23 | 69×4×Φ1 | 30 | |

| YLCn-200 | 8 | 120 | 1+1/2" | 6 | matched | 100×15.9×30 | Φ8.9×45 (diameter×length) | 69×7×Φ1 | 35 |

| YLCn-300 | 12 | 160 | 2" | 6 | matched | 100×15.9×32 | 69×7×Φ1 | 40 | |

| YLC-050 | 2 | 40 | DN25/1" | 6 | matched | 100×8.9×30 | 25×30×12 (L×H×w) | 60×4×Φ1 | 45 |

| YLC-150 | 6 | 80 | DN32/1 1/4 " | 6 | matched | 100×10.8×30 | 60×4×Φ1 | 50 | |

| YLC-200 | 8 | 120 | DN40/1 1/2 " | 6 | matched | 100×15.9×40 | 60×7×Φ1 | 60 | |

| YLC-300 | 12 | 160 | DN50/2" | 6 | matched | 100×15.9×40 | 60×7×Φ1 | 70 | |

| YLC-360 | 15 | 200 | DN65/2 1/2" | 6 | matched | 100×15.9×40 | 50×78×25 (L×H×W) | 60×7×Φ1 | 120 |

| YLC-500 | 20 | 240 | DN65/2 1/2" | 6 | matched | 100×21.9×50 | 60×11×Φ1.2 | 130 | |

| YLC-600 | 25 | 280 | DN80/3" | 6 | matched | 100×21.9×50 | 60×11×Φ1.2 | 140 | |

| YLC-700 | 30 | 320 | DN100/4" | 6 | matched | 100×21.9×50 | 60×11×Φ1.2 | 150 | |

| YLC-1000 | 40 | 360 | DN100/4" | 6 | matched | 100×21.9×50 | 60×11×Φ1.2 | 160 | |

| YLC-1200 | 50 | 400 | DN125/5" | 6 | matched | 100×21.9×50 | 60×11×Φ1.2 | 180 | |

| YLC-1500 | 60 | 420 | DN150/6" | 6 | matched | 170×27.3×57 | 120×16×Φ1.4 | 210 | |

| YLC-2000 | 80 | 560 | DN150/6" | 6 | matched | 170×27.3×57 | 120×16×Φ1.4 | 220 | |

| YLC-2500 | 100 | 700 | DN150/6" | 6 | matched | 170×27.3×57 | 60×128×30 (W×H×T) | 120×16×Φ1.4 | 275 |

| YLC-3000 | 125 | 840 | DN150/6" | 6 | matched | 173×27.3×57 | 120×16×Φ1.4 | 300 | |

| YLC-4000 | 150 | 1120 | DN200/8" | 6 | matched | 173×32.5×65 | 120×20×Φ1.6 | 325 | |

| YLC-5000 | 200 | 1400 | DN200/8" | 6 | matched | 173×37.7×72 | 120×22×Φ1.6 | 350 | |

| YLC-7000 | 300 | 2100 | DN250/10" | 6 | matched | 175×42.6×80 | 120×24×Φ2.0 | 400 | |

| YLC-10K | 400 | 2520 | DN250/10" | 6 | matched | 176×52.9×95 | 60×150×40 (W×H×T) | 120×28×Φ2.2 | 475 |

| YLC-15K | 600 | 3080 | DN300/12" | 6 | matched | 176×78×110 | 120×32×Φ2.4 | 600 | |

| YLC-20K | 800 | 3920 | DN350/14" | 6 | matched | confirmed | confirmed | confirmed | confirmed |

| YLC-25K | 1000 | 4760 | DN350/14" | 6 | matched | confirmed | confirmed | confirmed |

FAQ

Q. How does one properly size a UV system?

A. A UV system for a swimming pool is sized to match up with the water flow of the pool circulation pump(s). Consult the Ultra UV Owner's Manual to see which model Ultra UV system matches the flow rate of a specific circulation pump. Information accompanying the pump can provide this flow rate, as can the pump supplier's literature or website, or the dealer or installer that provided the pump. And, remember that the Ultra UV pool sanitizer is convertible to allow for increasing the killing power of the UV system if a system was selected originally that was undersized due to under estimating the pool's circulation pump output rate of flow.

Q. Do I still need to use chemicals in the pool?

A. As noted in the first question and answer, the Ultra UV pool sanitizer treats the water as it passes through the reactor chamber of the system. When organic materials, such as skin scrapings, urine, sweat, bird droppings, dust etc. enter the pool, there must be a low level of sanitizer present to treat the pool water until it reaches the UV reactor. Owners of UV systems report sanitizing chemical reductions of 50%-70% in many cases. Chemicals for control of pH, and other chemicals the pool owner may have used prior to the installation of their UV system should still be followed, as the Ultra UV system imparts nothing into the pool water when killing bacteria in the pool water. This is a real plus over alternate sanitizing methods that add chemicals to the pool water during the sanitization process.

Q. If chlorine is used after UV installation, will the chlorine smell still be present?

A. One of the side benefits of the Ultra UV system is its ability to reduce or eliminate mono-chloramine in the pool water. Chloramines are the by-products of chlorination and are the "chlorine smelly" odor associated with chlorinated pools. With proper Ultra UV sizing and chemical maintenance, the chloramine "chlorine" odor can be eliminated and the pool returned to a safe and enjoyable environment.

Q. How is the UV system installed in the average pool?

A. The Ultra UV pool samitizer installs in the circulation system, after the filter and before any heater or chemical injection points. Designed to accommodate 3 different pump output flow rate ranges up to 130 GPM (40.4 m3/hr), installing the Ultra UV system is a simple and low cost procedure for the pool builder or homeowner.

Q. Is the system available in the electrical power used in my country?

A. All Ultra UV systems are available in either 120V/50/60 Hz or 230V/50/60Hz electrical power.. Note: Do not operate the Ultra UV system on any power not indicated on the silver service plate on the front of the unit. These systems are NOT dual voltage. Contact us if you need more details on UV Sterilizer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ultraviolet Sterilizer、UV Disinfector. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Ultraviolet Sterilizer > UV Water Sterilizer

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)