Stainless Steel Bag Filter Housing 0.5um Liquid Filtration Water Purifcation

Basic Info

Model No.: YLF-B12

Product Description

Model NO.: YLF-B12 Usage: Liquid Filtration Style: Vertical Certification: CE Model Number: Ylf-B12 Use: High Filtration Precision Working Pressure: 0.1-0.3MPa Fluid: 90 to 1000 M3/Hour Flow Rate: 10-900m3/H Transport Package: Plywood Case Into Container Origin: Jiangyin, Jiangsu Type: Niphos Water Filter Motive Force: Pressure Performance: Efficient Filtration Material: Stainless Steel Quantity of Bag: From 2 to 24 PCS Brand Name: Yld Diameter of Flange: From 40mm to 450mm Application: Liquid Filtration Trademark: YLD Specification: CE, SGS HS Code: 8421219990 product introductionFilter Bag Housing SS are a lightweight, economical, industrial commercial design suitable for a wide variety of filtration applications. The 100% stainless steel and passivated finish provides superior corrosion resistance and an excellent appearance. The clamp type closure make cartridge change-out quick and easy.

304 or 316 stainless steel construction for best chemical compatibility and corrosion resistance. Low pressure drops, high filtration efficiency. Electro-polished external housing for superior finish. Easy access for housings cleaning or bags chang-out, no tool needed. Lid o-ring sealing between cover and housing, preventing liquid leakage. Patent-design bag posigioning ring provide positive sealing when used with APM filter bags, preventing bypass of unfiltered liquid. Heavy-duty bag support baskets. Multiple pressure ratings available. Swing bolts with eyenuts closure design. Standard pressure rating 150 psi (10 kg/cm2). 2"(APM11/12) or 1"(APM13/14) threaded or flanged inlet/outletas standard. Side inlet and bottom outlet as standard, other configurations are also available. Adjustable tripod leg. Standard models and custom designs available.

product features

1. the filtration precision is high, so it can be used for filtering particles of more than 0.2um at a time.

2. no filtering solution, adsorbent and catalyst can be adsorbed and damaged and no original components of the working medium can be changed.

3. it has good leakproofness and compact structure, so it is not easy to be damaged and is suitable for the production site with poor working conditions and no maintenance cost is needed.

4. easy disassembly and scientific and diversified filter structure, satisfying a variety of filtration requirements. automate production will be achieved through networking with pc.

scope of application Applications:

1. Water treatment:

Purification system for cooling equipments, oil-field flooding, solid free completion fluid filtration, condensation water purification for power station, wastewater treatment, pure water, condensation water, sea water desalinization, etc 2. Chemicals:

Reclaiming catalyzer, acid, alkali, adhesive, lubricating oil, etc.

3. Car manufacturing:

Electrophoretic coating filtration, hardener filtration, solvent filtration, etc.

4. Multimember:

Phosphate bath filtration, reclaiming precious metals, etc.

5. Electronic industry:

Printed-wiring board, galvanizing baths, wafer treatment liquid filtration, etc.

6. Fine chemicals:

Detergent filtration, coconut oil scouring, etc.

7. Petrochemical industry:

Reclaiming oil, elucidation of oil and gas, chloramine-T filtration, paint, resin, printing oil, etc. 8. Food and beverage:

Fruit juice, beer, drinking water, sauger, etc. micron filter lter housing | 9. Pharmaceuticals industry:

Reclaiming GMP, vitamin extraction, reclaiming protein and activated carbon, etc

Technical Parameters:

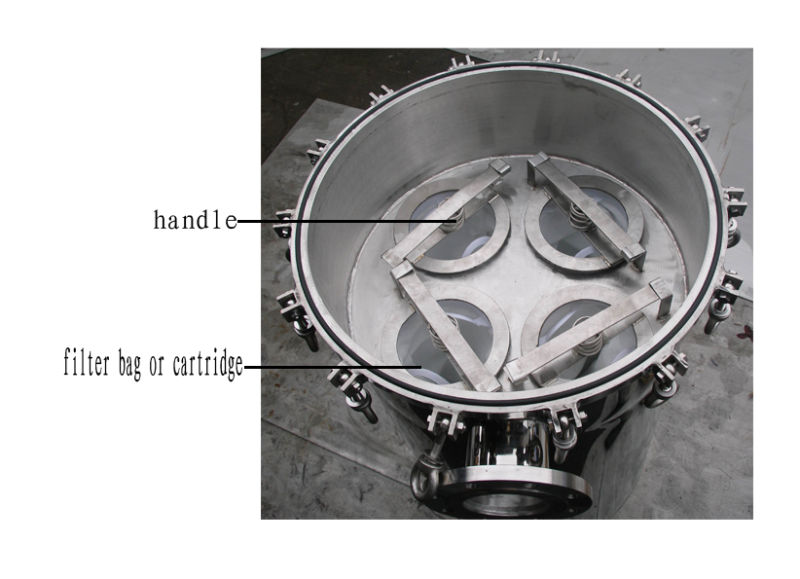

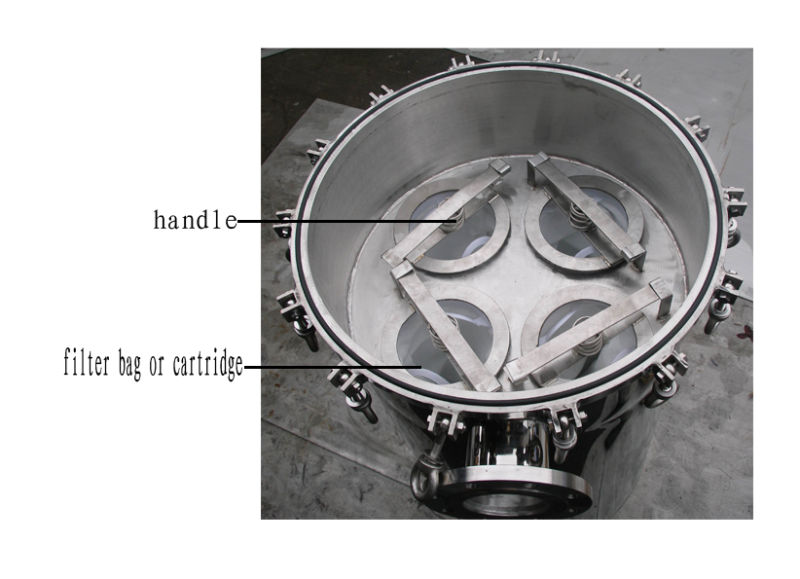

Bag Filter Housing Working Principle Bag Filter is a widely used for liquid filtration,it can remove the particles of different size from liquid,in order to achieve liquid filtration,purification,separation,recovery purposes.It consists of three parts:bag housing,supporting basket and filter bags.According to flow rate,you may use multiple bags in a bag housing.First,the liquid enter into the housing from the inlet,which may placed in the side or on the top,and then flow into the filter bag which is braced by basket.Due to the impact pressure of fluid,the bag will extend and the liquid get evenly filtered through the bag and flow out of the outlet pipe.Impurities are trapped in the bag,the filtration process is complete.When you replace or clean the bag,just simply loosen the bolt,rotary hand wheel lifting the lid,and get the bag.

Bag Filter Housing Working Principle Bag Filter is a widely used for liquid filtration,it can remove the particles of different size from liquid,in order to achieve liquid filtration,purification,separation,recovery purposes.It consists of three parts:bag housing,supporting basket and filter bags.According to flow rate,you may use multiple bags in a bag housing.First,the liquid enter into the housing from the inlet,which may placed in the side or on the top,and then flow into the filter bag which is braced by basket.Due to the impact pressure of fluid,the bag will extend and the liquid get evenly filtered through the bag and flow out of the outlet pipe.Impurities are trapped in the bag,the filtration process is complete.When you replace or clean the bag,just simply loosen the bolt,rotary hand wheel lifting the lid,and get the bag.

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oil Filter、Water Treatment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oil Filter、Water Treatment. If these products fail to match your need, please contact us and we would like to provide relevant information.

304 or 316 stainless steel construction for best chemical compatibility and corrosion resistance. Low pressure drops, high filtration efficiency. Electro-polished external housing for superior finish. Easy access for housings cleaning or bags chang-out, no tool needed. Lid o-ring sealing between cover and housing, preventing liquid leakage. Patent-design bag posigioning ring provide positive sealing when used with APM filter bags, preventing bypass of unfiltered liquid. Heavy-duty bag support baskets. Multiple pressure ratings available. Swing bolts with eyenuts closure design. Standard pressure rating 150 psi (10 kg/cm2). 2"(APM11/12) or 1"(APM13/14) threaded or flanged inlet/outletas standard. Side inlet and bottom outlet as standard, other configurations are also available. Adjustable tripod leg. Standard models and custom designs available.

product features

1. the filtration precision is high, so it can be used for filtering particles of more than 0.2um at a time.

2. no filtering solution, adsorbent and catalyst can be adsorbed and damaged and no original components of the working medium can be changed.

3. it has good leakproofness and compact structure, so it is not easy to be damaged and is suitable for the production site with poor working conditions and no maintenance cost is needed.

4. easy disassembly and scientific and diversified filter structure, satisfying a variety of filtration requirements. automate production will be achieved through networking with pc.

scope of application Applications:

1. Water treatment:

Purification system for cooling equipments, oil-field flooding, solid free completion fluid filtration, condensation water purification for power station, wastewater treatment, pure water, condensation water, sea water desalinization, etc 2. Chemicals:

Reclaiming catalyzer, acid, alkali, adhesive, lubricating oil, etc.

3. Car manufacturing:

Electrophoretic coating filtration, hardener filtration, solvent filtration, etc.

4. Multimember:

Phosphate bath filtration, reclaiming precious metals, etc.

5. Electronic industry:

Printed-wiring board, galvanizing baths, wafer treatment liquid filtration, etc.

6. Fine chemicals:

Detergent filtration, coconut oil scouring, etc.

7. Petrochemical industry:

Reclaiming oil, elucidation of oil and gas, chloramine-T filtration, paint, resin, printing oil, etc. 8. Food and beverage:

Fruit juice, beer, drinking water, sauger, etc. micron filter lter housing | 9. Pharmaceuticals industry:

Reclaiming GMP, vitamin extraction, reclaiming protein and activated carbon, etc

Technical Parameters:

| Model | Flow rate (T/H) | inlet and outlet diameter | Quantity of the bags | Filter size | Specifications | Filtration Area |

| YL-1-219 | 20 | DN50mm | 1 | 219*410 | 180*410 | 0.23 |

| YL-2-219 | 40 | DN65mm | 1 | 219*810 | 180*410 | 0.46 |

| YL-2-400 | 50-80 | DN80mm | 2 | 400*810 | 180*810 | 0.92 |

| YL-2-500 | 120 | DN100mm | 3 | 500*810 | 180*810 | 1.38 |

| YL-2-550 | 140 | DN100mm | 4 | 5500*810 | 180*810 | 1.8 |

| YL-2-600 | 150 | DN125mm | 4 | 600*810 | 180*810 | 1.8 |

| YL-2-650 | 160 | DN125mm | 5 | 650*810 | 180*810 | 1.84 |

| YL-2-750 | 200 | DN150mm | 6 | 750*810 | 180*810 | 2.3 |

| YL-2-800 | 220 | DN100mm | 8 | 800*810 | 180*810 | 2.5 |

| YL-2-850 | 240 | DN200mm | 9 | 850*810 | 180*810 | 2.76 |

Bag Filter Housing Working Principle Bag Filter is a widely used for liquid filtration,it can remove the particles of different size from liquid,in order to achieve liquid filtration,purification,separation,recovery purposes.It consists of three parts:bag housing,supporting basket and filter bags.According to flow rate,you may use multiple bags in a bag housing.First,the liquid enter into the housing from the inlet,which may placed in the side or on the top,and then flow into the filter bag which is braced by basket.Due to the impact pressure of fluid,the bag will extend and the liquid get evenly filtered through the bag and flow out of the outlet pipe.Impurities are trapped in the bag,the filtration process is complete.When you replace or clean the bag,just simply loosen the bolt,rotary hand wheel lifting the lid,and get the bag.

Bag Filter Housing Working Principle Bag Filter is a widely used for liquid filtration,it can remove the particles of different size from liquid,in order to achieve liquid filtration,purification,separation,recovery purposes.It consists of three parts:bag housing,supporting basket and filter bags.According to flow rate,you may use multiple bags in a bag housing.First,the liquid enter into the housing from the inlet,which may placed in the side or on the top,and then flow into the filter bag which is braced by basket.Due to the impact pressure of fluid,the bag will extend and the liquid get evenly filtered through the bag and flow out of the outlet pipe.Impurities are trapped in the bag,the filtration process is complete.When you replace or clean the bag,just simply loosen the bolt,rotary hand wheel lifting the lid,and get the bag.

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oil Filter、Water Treatment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oil Filter、Water Treatment. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Water Filter > Bag Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)