Stainless Steel Filter Cartridge Automatic Backwash Water Filter

Basic Info

Model No.: YLF-200

Product Description

Model NO.: YLF-200 Usage: Environmental Protection Style: Vertical Certification: CE, GS Filtration Degree: 50 to 1500 Micros Working Temperature: Less Than 100 Centigrade Nos of Ss Cartridge: 3--24 PCS Trademark: YLD Origin: Jiangyin, China Type: Water Filter Motive Force: Electric power Performance: Efficient Filtration Material: Carbon Steel,Ss304,Ss316,Ss316L,Ss2205 Working Pressure: 0.6/1.0/1.6MPa Filter Cartridge: Ss304/Ss316/Ss316L Electricity Power Supply: 380V,50Hz,3 Phase, or Customized Specification: to be based practical size HS Code: 842121999

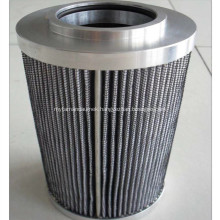

Multi cartridge self cleaning filter

Multi cartridge self cleaning filter is widely used in a variety of water supply systems, process water systems and industrial cooling water systems, especially the 24 hours of continuous operation without stopping the machine system, a variety of mechanical impurities, water can be filtered to ensure the safety of the system equipment and reliableoperation.

Structure and working principle

Automatic backflush filter composed of high quality carbon steel cylinder, the special structure of the stainless steel deed shaped strainer, butterfly valve and sewage installations. When the filters work, the butterfly valve is turned on, the water flow from the inlet into the filter, filter-filter to export. When the filters need to sewage, close the butterfly valve, open the drain valve, the second half of the filter of the flow through the filter before export into the system, some water, the remaining water from the filter after the first half of the outside into the inside through the outfall discharge, since automatic flushing to reverse the role of the filter. The entire process of flushing the system can work properly, with no downtime .

Application Fields

1.A domestic water production process water supply filter.

2.Ultrafiltration, Reverse Osmosis, softening, ion exchange pretreatment.

3.Seafood nursery Water Purification factory marine and freshwater aquaculture water filter.

4.The oil field injection water filter.

5.The circulating cooling water filtration.

6.Water reuse, advanced wastewater treatment filter.

7.Iron and steel, petroleum, chemical, paper, automobiles, food, metallurgy and other industries cycle water filtration.

8.Groundwater, surface water turbidity removal purification.

9.Central air conditioning, boiler return water filter

10.Certain requirements on water quality equipment water supply filter.

11.Swimming pools, landscape water purification.

12.Municipal, green spray, irrigation, agricultural irrigation, drip irrigation with the filter.

Technical feature

1.A high filtration precision, water quality and stability.

2.Through its own retrieval and response function, automatic backwash can cope with the instability of the water quality fluctuations, without human intervention.

3.Control system is responsive, precise operation, differential pressure and time setting function can be flexibly adjusted according to different sources of water and filtering accuracy backwash pressure or time settings.

4.Cleaning efficient and thorough, the filter could completely restore the initial state, and thus life, without replacement.

5.Backwash without interrupting the normal production of water in continuous operation, stable and reliable.

6.The backwash short duration, backwash water consumption is only 0.001-0.002% of the normal water production, water-saving, energy saving, energy conservation.

7.The structural design of reasonably compact, small footprint, flexible installation of mobile.

8.Equipment vulnerable small, no supplies, low operation and maintenance costs, simple operation and management.

9 wide applications, suitable for different raw water quality and water requirements.

Technical parameter

Working pressure: ≤ 1.0MPa

Operating temperature: ≤ 100 ° C

Pressure Loss: ≤ 0.015MPa

Filter precision: d = 1.0mm

Other: work pressure, filtration precision and specification size according to user require special manufacturing, flange connecting dimensions according to GB-9119.8-88.

Installation and use

Automatic recoil filter should be installed horizontally or vertically, when mounted vertically, the flow direction is from top to bottom, the installation should pay attention to the direction of the arrow on the housing must be consistent with the water during normal operation, the butterfly valve is turnedwhen the need of sewage, close the butterfly valve, open the drain valve until the discharge water quality clear so far. Close the drain valve, open the butterfly valve to complete the process of sewage, and equipment in normal operation.

Technical parameter

Contact us if you need more details on Multi-Cartrdige Ss Filter Housing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Backwash Filter、Self Cleaning Water Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Multi cartridge self cleaning filter

Multi cartridge self cleaning filter is widely used in a variety of water supply systems, process water systems and industrial cooling water systems, especially the 24 hours of continuous operation without stopping the machine system, a variety of mechanical impurities, water can be filtered to ensure the safety of the system equipment and reliableoperation.

Structure and working principle

Automatic backflush filter composed of high quality carbon steel cylinder, the special structure of the stainless steel deed shaped strainer, butterfly valve and sewage installations. When the filters work, the butterfly valve is turned on, the water flow from the inlet into the filter, filter-filter to export. When the filters need to sewage, close the butterfly valve, open the drain valve, the second half of the filter of the flow through the filter before export into the system, some water, the remaining water from the filter after the first half of the outside into the inside through the outfall discharge, since automatic flushing to reverse the role of the filter. The entire process of flushing the system can work properly, with no downtime .

Application Fields

1.A domestic water production process water supply filter.

2.Ultrafiltration, Reverse Osmosis, softening, ion exchange pretreatment.

3.Seafood nursery Water Purification factory marine and freshwater aquaculture water filter.

4.The oil field injection water filter.

5.The circulating cooling water filtration.

6.Water reuse, advanced wastewater treatment filter.

7.Iron and steel, petroleum, chemical, paper, automobiles, food, metallurgy and other industries cycle water filtration.

8.Groundwater, surface water turbidity removal purification.

9.Central air conditioning, boiler return water filter

10.Certain requirements on water quality equipment water supply filter.

11.Swimming pools, landscape water purification.

12.Municipal, green spray, irrigation, agricultural irrigation, drip irrigation with the filter.

Technical feature

1.A high filtration precision, water quality and stability.

2.Through its own retrieval and response function, automatic backwash can cope with the instability of the water quality fluctuations, without human intervention.

3.Control system is responsive, precise operation, differential pressure and time setting function can be flexibly adjusted according to different sources of water and filtering accuracy backwash pressure or time settings.

4.Cleaning efficient and thorough, the filter could completely restore the initial state, and thus life, without replacement.

5.Backwash without interrupting the normal production of water in continuous operation, stable and reliable.

6.The backwash short duration, backwash water consumption is only 0.001-0.002% of the normal water production, water-saving, energy saving, energy conservation.

7.The structural design of reasonably compact, small footprint, flexible installation of mobile.

8.Equipment vulnerable small, no supplies, low operation and maintenance costs, simple operation and management.

9 wide applications, suitable for different raw water quality and water requirements.

Technical parameter

Working pressure: ≤ 1.0MPa

Operating temperature: ≤ 100 ° C

Pressure Loss: ≤ 0.015MPa

Filter precision: d = 1.0mm

Other: work pressure, filtration precision and specification size according to user require special manufacturing, flange connecting dimensions according to GB-9119.8-88.

Installation and use

Automatic recoil filter should be installed horizontally or vertically, when mounted vertically, the flow direction is from top to bottom, the installation should pay attention to the direction of the arrow on the housing must be consistent with the water during normal operation, the butterfly valve is turnedwhen the need of sewage, close the butterfly valve, open the drain valve until the discharge water quality clear so far. Close the drain valve, open the butterfly valve to complete the process of sewage, and equipment in normal operation.

Technical parameter

| Model | Capacity (m³/hour) | Inlet-outlet (mm) | Drain (mm) | D (mm) | H (mm) | H1 (mm) | H2 (mm) |

| YLF-50 | 70 | DN50 | DN50 | 300 | 1690 | 265 | 640 |

| YLF-80 | 80 | DN80 | DN50 | 350 | 1720 | 265 | 660 |

| YLF-100 | 120 | DN100 | DN50 | 400 | 1760 | 265 | 680 |

| YLF-200 | 200 | DN200 | DN80 | 500 | 1860 | 290 | 715 |

| YLF-250 | 280 | DN250 | DN80 | 600 | 1930 | 290 | 755 |

| YLF-300 | 450 | DN300 | DN100 | 700 | 2040 | 335 | 755 |

| YLF-350 | 600 | DN350 | DN100 | 800 | 2105 | 335 | 770 |

| YLF-400 | 800 | DN400 | DN100 | 1000 | 2220 | 335 | 800 |

| YLF-500 | 1000 | DN500 | DN100 | 1200 | 2360 | 365 | 825 |

Contact us if you need more details on Multi-Cartrdige Ss Filter Housing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Backwash Filter、Self Cleaning Water Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Filter > Automatic Backwash Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)