Pressure Sand Filter Pre Filtration for Membrane Systems

Basic Info

Model No.: YLD-MF-500

Product Description

Model NO.: YLD-MF-500 Usage: Environmental Protection, Chemical Industry, Water Treatment Style: Vertical Certification: CE Filtration Material: Quartz Sand, Active Carbon, Mn Sand, etc Pressure Loss: Less Than 0.02% Water Flowing Speed: 10 --15 M/Hour Application Field: RO System, Water Treatment Plant Flow Rate: 2 Ton Per Hour Specification: to be practical HS Code: 842121999 Type: Quartz Sand Motive Force: Electric power Performance: Efficient Filtration Material: Carbon Steel(Midl Steel), Ss304, Ss316, Ss2205 Working Pressure: 0.6/1.0MPa Working Temperature: No More Than 40 C Water Output: <5 Ntu Function: Water Filter Trademark: YLD Origin: Jiangyin, China Pressure Sand Filter Pre Filtration For Membrane Systems

Pressure Sand Filter is highly recommended for the removal of suspended solids & undissolved impurities like dust particles & heavy metals etc. PSF reduces turbidity.

Pressure Sand Filter is an ideal solution for the systems with high sediment, silt, sand, and turbidity. The sand filters are specially designed to take care of the range of suspended impurities. Our unique design ensures the maximum utilization of the surface area, lesser pressure drop across the pressure bed and effective elimination of the impurities.

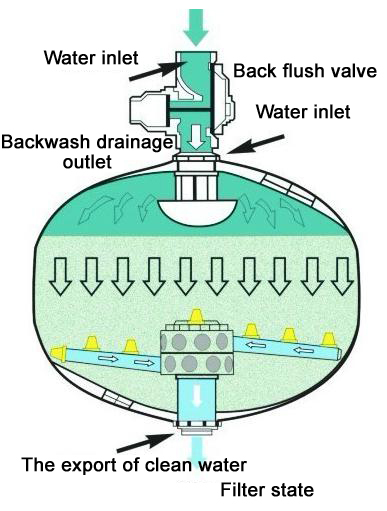

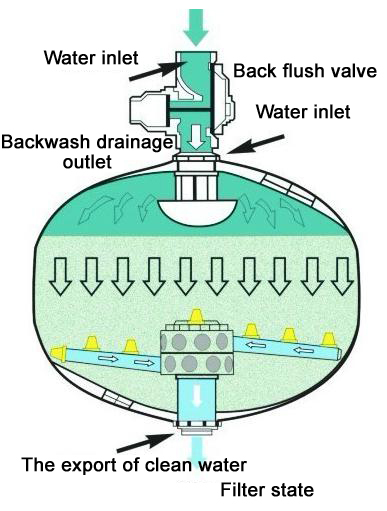

Working Principle:

Raw water is passed through the pressure sand filter, the filter media is supported on gravel bed that consists of multiple layers of Graded quartz sand, Fine sand, Super fine white sand and pebbles of progressively larger sizes. During the filtration cycle the filter bed retains the dirt and suspended particles from the water and accumulates within the filter the water and accumulates within the filter bed. As the filtration progress the filter media gets loaded with retained suspended particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning.

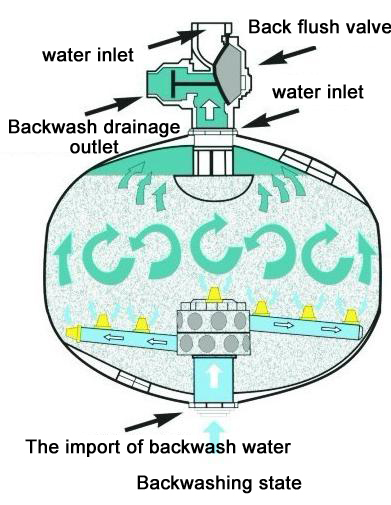

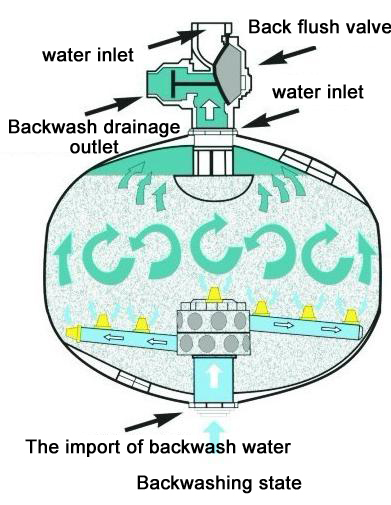

Back Wash

As the filtration progress the filter media gets loaded with the retain the suspended particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning. The filter media is cleaned by backwash system. After backwashing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back into service. Depending on the filtered water quality required backwashing is either done with raw water or with filtered water.

Salient Features / Advantages

Efficient Turbidity and TSS Removal

Filter up to 20 - 30 Microns

FRP, MSRL, MSEP & SS Vessel available.

Standard and effective multi grade sand media.

Low Pressure drop across the vessel

Air scouring available for high flow pressure vessel.

Manual, Semi Automatic and Automatic features are provided

Advantages

Easy operation & maintenance

Wide range in material of construction

Filtration efficiency is up to 0.2 ppm suspended particles

Economical way of production & designee

System is based on washable process, so it works in continue operation required

Replacement of filtering media is very easy and it work for longer period

Applications for sand filtration

Preparation of cooling water

Treatment of waste water

Production of drinking water

Filtration in swimming pools

Pre filtration for membrane systems

Filtration of gray or surface water

Swimming pool water

AAA:

01. how small a solid needs to be removed,

02. how dirty the water is,

03. how the water will be used once it is filtered,

04. and the source of backwash water needed to clean the filters.

Technical parameters sheet for Mechanical actived carbon filter

Contact us if you need more details on Sand Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Filters、Reverse Osmosis. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Sand Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Filters、Reverse Osmosis. If these products fail to match your need, please contact us and we would like to provide relevant information.

Pressure Sand Filter is highly recommended for the removal of suspended solids & undissolved impurities like dust particles & heavy metals etc. PSF reduces turbidity.

Pressure Sand Filter is an ideal solution for the systems with high sediment, silt, sand, and turbidity. The sand filters are specially designed to take care of the range of suspended impurities. Our unique design ensures the maximum utilization of the surface area, lesser pressure drop across the pressure bed and effective elimination of the impurities.

Working Principle:

Raw water is passed through the pressure sand filter, the filter media is supported on gravel bed that consists of multiple layers of Graded quartz sand, Fine sand, Super fine white sand and pebbles of progressively larger sizes. During the filtration cycle the filter bed retains the dirt and suspended particles from the water and accumulates within the filter the water and accumulates within the filter bed. As the filtration progress the filter media gets loaded with retained suspended particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning.

Back Wash

As the filtration progress the filter media gets loaded with the retain the suspended particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning. The filter media is cleaned by backwash system. After backwashing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back into service. Depending on the filtered water quality required backwashing is either done with raw water or with filtered water.

Salient Features / Advantages

Efficient Turbidity and TSS Removal

Filter up to 20 - 30 Microns

FRP, MSRL, MSEP & SS Vessel available.

Standard and effective multi grade sand media.

Low Pressure drop across the vessel

Air scouring available for high flow pressure vessel.

Manual, Semi Automatic and Automatic features are provided

Advantages

Easy operation & maintenance

Wide range in material of construction

Filtration efficiency is up to 0.2 ppm suspended particles

Economical way of production & designee

System is based on washable process, so it works in continue operation required

Replacement of filtering media is very easy and it work for longer period

Applications for sand filtration

Preparation of cooling water

Treatment of waste water

Production of drinking water

Filtration in swimming pools

Pre filtration for membrane systems

Filtration of gray or surface water

Swimming pool water

AAA:

01. how small a solid needs to be removed,

02. how dirty the water is,

03. how the water will be used once it is filtered,

04. and the source of backwash water needed to clean the filters.

Technical parameters sheet for Mechanical actived carbon filter

| TPYE | TANK SIZE (mm) | TOTAL HIGH (mm) | FLOW RATE (m3/hr) | INLET AND OUTLET (mm) | QUARTZ SAND (t) |

| YLD-MF-500 | 500*1500 | 2350 | 2 | DN32 | 0.39 |

| YLD-MF- 600 | 600*1500 | 2380 | 2-3 | DN32 | 0.56 |

| YLD-MF- 700 | 700*1500 | 2400 | 4 | DN40 | 0.76 |

| YLD-MF- 800 | 800*1500 | 2400 | 5 | DN40 | 1 |

| YLD-MF- 900 | 900*1500 | 2500 | 6 | DN50 | 1.3 |

| YLD-MF- 1000 | 1000*1500 | 2600 | 8 | DN50 | 1.6 |

| YLD-MF- 1200 | 1200*1500 | 2700 | 11 | DN65 | 2.3 |

| YLD-MF- 1400 | 1400*1500 | 2800 | 15 | DN65 | 3 |

| YLD-MF- 1500 | 1500*1500 | 2850 | 18 | DN65 | 3.5 |

| YLD-MF- 1600 | 1600*1500 | 2900 | 20 | DN80 | 4 |

| YLD-MF- 1800 | 1800*1500 1800*1800 | 3000 | 25 | DN80 | 5 |

| YLD-MF- 2000 | 2000*1500 | 3100 | 30 | DN100 | 6 |

| YLD-MF- 2200 | 2200*1500 | 3180 | 38 | DN100 | 7.5 |

| YLD-MF- 2400 | 2400*1500 | 3330 | 45 | DN100 | 9 |

| YLD-MF- 2500 | 2500*1500 | 3380 | 50 | DN100 | 9.7 |

| YLD-MF- 2600 | 2600*1500 | 3430 | 55 | DN125 | 10 |

| YLD-MF- 2800 | 2800*1500 | 3530 | 60 | DN125 | 12.5 |

| YLD-MF- 3000 | 3000*1500 | 3630 | 70-80 | DN125 | 14 |

| YLD-MF- 3200 | 3200*1500 | 3730 | 80~100 | DN150 | 16 |

Contact us if you need more details on Sand Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Filters、Reverse Osmosis. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Sand Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Filters、Reverse Osmosis. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Sand Filter > Media Sand Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)