Food Grade Material UV Water Sterilizer for Drinking Water Treatment

Basic Info

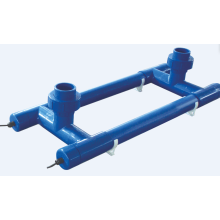

Model No.: YLC-700

Product Description

Model NO.: YLC-700 Application: Industry Disinfection Method: Ultraviolet Material: Stainless Steel Ss304, Ss316 Lifespan of UV Lamp: 9000-12000 Hours Flow Rate: 30 Ton/Hour System Working Pressure Resistance: (0.6 MPa)6kg/Cm2 Brand of Ballast: Beasun Specification: CE, SGS HS Code: 8421219990 Certification: BV, ISO9001, SGS, CE Voltage: 110V/220V/380V Bactericidal Efficienc: 98% Kill Total Coliforms Medium Material: PP (Propene Polymer) Interface Type: Flange or Thread Alert System for Lamp: Have Raw Water Supplying: Running Water Trademark: YLD Origin: Jiangyin, Jiangsu

Food Grade Material UV Water Sterilizer For Drinking Water Treatment

Questions:

Q. How do ultraviolet ("UV") sterilizers work?

A. UV sterilizers work by exposing water to powerful germicidal ultraviolet light. DNA and protein links in bacteria are destroyed by exposure to this light.

Q. Does the water become radioactive by this radiation?

A. No. No radiation residual or any chemical residual is left in the water as a result of the UV rays.

Q. Do these systems come in different sizes?

A. Yes. The size of the systems is directly proportional to the flow rate of the water in gallons per minute. The higher the flow rate, the larger the system and lamp.

Q. Does the water have to sit in the UV Sterilizer to be disinfected?

A. No. If the system is sized correctly, the water is disinfected as it flows through.

Q. What if the water flows faster than is allowed through the system?

A. If the flow rate exceeds the design flow rate of the UV sterilizer, then there is a possibility that the water will not be properly disinfected. It is important to use a flow restrictor so that the flow rate cannot be exceeded.

Q. How long does the lamp last?

A. The lamps last approximately 10,000 hours. That is why we recommend replacement approximately every 12 - 14 months of continuous operation. After this period, the lamp itself becomes solarized and blocks the rays form entering the water.

Q. Are these systems bigger energy users?

A. No. The 12 gallon per minute model, for instance uses only 39 watts, about half the amount an ordinary light bulb uses.

Q. My water is sometimes cloudy. Is that a problem?

A. Yes. The water that enters the Ultraviolet Sterilizer must be absolutely clear and have a turbidity of less than 1 NTU. If your water is cloudy, then it must be pretreated.

Q. My water is very high in hardness and iron. Is that a problem?

A. Yes. The water to be sterilized must be free of iron, manganese, tannins, and other minerals that can build up on the quartz sleeve. Some of our UV sterilizers come with wipers that allow cleaning of the UV sterilizer quartz sleeve without disassembly. The quartz sleeve should be periodically inspected to make sure it is clean. Use an iron filter, or a softener ahead of the UV sterilizer for trouble-free operation if you are on well water high in iron or hardness.

Q. How can I tell if it is working?

A. All of the systems come with a "glow plug" so you can tell if the lamp is glowing. You can also order an optional light monitor that actually measures the rays and lets you see the intensity. The product water should be periodically tested for coliforms.

Q. What if the power goes off?

A. If the power goes off, no disinfection will take place if water flows through the system. If power failures are common, a fail-safe optional solenoid valve can be installed that shuts off all water flowing if the power goes off.

Q. What types of microorganisms will ultraviolet sterilizers inactivate?

A. These systems will easily destroy Influenza, Staphylococcus, Fecal Coliform, Salmonella, Legionella, Pneurnophila, Dysentery Bacilli and many other types. Cysts may be damaged, but for cysts (Giardia, Cryptosporidium) we recommend pre-filtration with cyst-certified filter systems, typically 1 micron or less absolute. Ultraviolet sterilizers are frequently paired up with filtration, softening or other types of treatment.

Ultraviolet or "UV" is a type of energy found in the electromagnetic spectrum lying between x-rays and visible light. Ultraviolet is divided into four basic sections: UV-V, UV-A, UV-B and UV-C. It is the UV-C, or germicidal UV, specifically the 265nm wavelength of UV-C that offers disinfection. The ultraviolet energy attacks the genetic core of the harmful microorganism and rearranges the DNA/RNA preventing reproduction. If the microbe can not replicate, it cannot infect! UV is quick and the most cost effective way to disinfect your water.

Is UV 100% effective?

UV disinfection typically offers a 99.99% reduction in both bacteria and virus and is more effective than chemical disinfection processes at destroying viruses.

Will UV change the taste or smell of my water?

UV is a physical disinfection process, no additives are required. It does not change the taste or odour of the water. It simply provides safe reliable disinfection.

How do I know the system is working?

All UV systems come with "lamp-out" monitors which give an audible and visual signal in case of lamp failure. Sterilight GOLD systems incorporate true UV intensity monitors so an alarm will sound if the disinfection effectiveness falls below a safe level.

Why do I need Disinfection?

Disinfection is required on all water supplies that are not protected by a municipal water source. Due to the uncertainties that exist within some water systems, we can no longer rely on the fact that our water supplies "may be safe." By providing your own disinfection, you are taking the responsibility of ensuring the safety of the water supply for you and your family.

Do I need to Disinfect My Municipal Water Supply?

Our municipalities work very hard to provide safe disinfected water supplies to their customers. However, you may wish to give yourself that added "peace of mind" and install a UV sterilizer to protect against the possibility of drinking contaminated water.

What are the annual maintenance requirements?

UV systems contain no mechanical parts that wear out or require maintenance. UV lamps have a useful life of approximately 8,000 hours and require replacement annually. Proper maintenance of any pretreatment system is also required.

Should I be concerned about the adequacy of my electrical system?

The UV system requires consistent power, both voltage and frequency. To compensate for the fluctuations in power supplies, Sterilight systems incorporate proprietary ICE ballast technology to provide constant output voltage regardless of the fluctuations. This results in consistent UV output and UV dose. What size of system do I need? An average household UV range in size from 5 to 12 gpm. Determining your pumps flow rate will typically determine your required flow rate. (Sterilight offers many different models in sizes ranging from 1/2 gpm to 1,000 gpm.)

Should I shut my system off when I am not using it?

The UV system should be left on at all times. By leaving the unit on, you will eliminate the potential problem of having contamination pass through the system while the unit is off.

Do I need to worry about the quality of my water prior to the UV?

For UV to be effective, it is recommended that the influent water contain less than the following:

iron less than 0.3 ppm

hydrogen sulphide less than 10 ppm

suspended solids less than 10 ppm

manganese less than 0.05

ppm hardness less than 7 gpg.

All conditions are treatable. To obtain adequate water quality for the UV, please consult your local water treatment professional for further assistance. To validate the disinfection process, it is important to have the water tested for bacteriological contaminants on a regular basis.

Why Ultraviolet?

Ultraviolet is a safe, clean, easy to maintain method of assuring that water is free of bacteria. It is a proven technology that has no significant drawbacks. In some applications, its initial cost is a bit more than chlorination, but because of its low operating cost, it quickly pays for itself. It is essentially trouble-free. Most systems require only an annual change of lamp--like changing a light bulb--and a change of filter cartridges if the unit has accompanying filters.

RFQ:

There are some details that i should confirm with your before our

design and quote.

01.What is the source of raw water to be treated?

--is it underground water or well water?or river water ,other source?

02.What is the capacity(m3/hour) you required for this sterilizer?

--most IMPORTANT requirement.

03.What will the treated water be used for?

--for human drinking or industry purpose?

Contact us if you need more details on Sterilizer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about UV Water Sterilizer、Drinking Water Treatment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Food Grade Material UV Water Sterilizer For Drinking Water Treatment

Questions:

Q. How do ultraviolet ("UV") sterilizers work?

A. UV sterilizers work by exposing water to powerful germicidal ultraviolet light. DNA and protein links in bacteria are destroyed by exposure to this light.

Q. Does the water become radioactive by this radiation?

A. No. No radiation residual or any chemical residual is left in the water as a result of the UV rays.

Q. Do these systems come in different sizes?

A. Yes. The size of the systems is directly proportional to the flow rate of the water in gallons per minute. The higher the flow rate, the larger the system and lamp.

Q. Does the water have to sit in the UV Sterilizer to be disinfected?

A. No. If the system is sized correctly, the water is disinfected as it flows through.

Q. What if the water flows faster than is allowed through the system?

A. If the flow rate exceeds the design flow rate of the UV sterilizer, then there is a possibility that the water will not be properly disinfected. It is important to use a flow restrictor so that the flow rate cannot be exceeded.

Q. How long does the lamp last?

A. The lamps last approximately 10,000 hours. That is why we recommend replacement approximately every 12 - 14 months of continuous operation. After this period, the lamp itself becomes solarized and blocks the rays form entering the water.

Q. Are these systems bigger energy users?

A. No. The 12 gallon per minute model, for instance uses only 39 watts, about half the amount an ordinary light bulb uses.

Q. My water is sometimes cloudy. Is that a problem?

A. Yes. The water that enters the Ultraviolet Sterilizer must be absolutely clear and have a turbidity of less than 1 NTU. If your water is cloudy, then it must be pretreated.

Q. My water is very high in hardness and iron. Is that a problem?

A. Yes. The water to be sterilized must be free of iron, manganese, tannins, and other minerals that can build up on the quartz sleeve. Some of our UV sterilizers come with wipers that allow cleaning of the UV sterilizer quartz sleeve without disassembly. The quartz sleeve should be periodically inspected to make sure it is clean. Use an iron filter, or a softener ahead of the UV sterilizer for trouble-free operation if you are on well water high in iron or hardness.

Q. How can I tell if it is working?

A. All of the systems come with a "glow plug" so you can tell if the lamp is glowing. You can also order an optional light monitor that actually measures the rays and lets you see the intensity. The product water should be periodically tested for coliforms.

Q. What if the power goes off?

A. If the power goes off, no disinfection will take place if water flows through the system. If power failures are common, a fail-safe optional solenoid valve can be installed that shuts off all water flowing if the power goes off.

Q. What types of microorganisms will ultraviolet sterilizers inactivate?

A. These systems will easily destroy Influenza, Staphylococcus, Fecal Coliform, Salmonella, Legionella, Pneurnophila, Dysentery Bacilli and many other types. Cysts may be damaged, but for cysts (Giardia, Cryptosporidium) we recommend pre-filtration with cyst-certified filter systems, typically 1 micron or less absolute. Ultraviolet sterilizers are frequently paired up with filtration, softening or other types of treatment.

Ultraviolet or "UV" is a type of energy found in the electromagnetic spectrum lying between x-rays and visible light. Ultraviolet is divided into four basic sections: UV-V, UV-A, UV-B and UV-C. It is the UV-C, or germicidal UV, specifically the 265nm wavelength of UV-C that offers disinfection. The ultraviolet energy attacks the genetic core of the harmful microorganism and rearranges the DNA/RNA preventing reproduction. If the microbe can not replicate, it cannot infect! UV is quick and the most cost effective way to disinfect your water.

Is UV 100% effective?

UV disinfection typically offers a 99.99% reduction in both bacteria and virus and is more effective than chemical disinfection processes at destroying viruses.

Will UV change the taste or smell of my water?

UV is a physical disinfection process, no additives are required. It does not change the taste or odour of the water. It simply provides safe reliable disinfection.

How do I know the system is working?

All UV systems come with "lamp-out" monitors which give an audible and visual signal in case of lamp failure. Sterilight GOLD systems incorporate true UV intensity monitors so an alarm will sound if the disinfection effectiveness falls below a safe level.

Why do I need Disinfection?

Disinfection is required on all water supplies that are not protected by a municipal water source. Due to the uncertainties that exist within some water systems, we can no longer rely on the fact that our water supplies "may be safe." By providing your own disinfection, you are taking the responsibility of ensuring the safety of the water supply for you and your family.

Do I need to Disinfect My Municipal Water Supply?

Our municipalities work very hard to provide safe disinfected water supplies to their customers. However, you may wish to give yourself that added "peace of mind" and install a UV sterilizer to protect against the possibility of drinking contaminated water.

What are the annual maintenance requirements?

UV systems contain no mechanical parts that wear out or require maintenance. UV lamps have a useful life of approximately 8,000 hours and require replacement annually. Proper maintenance of any pretreatment system is also required.

Should I be concerned about the adequacy of my electrical system?

The UV system requires consistent power, both voltage and frequency. To compensate for the fluctuations in power supplies, Sterilight systems incorporate proprietary ICE ballast technology to provide constant output voltage regardless of the fluctuations. This results in consistent UV output and UV dose. What size of system do I need? An average household UV range in size from 5 to 12 gpm. Determining your pumps flow rate will typically determine your required flow rate. (Sterilight offers many different models in sizes ranging from 1/2 gpm to 1,000 gpm.)

Should I shut my system off when I am not using it?

The UV system should be left on at all times. By leaving the unit on, you will eliminate the potential problem of having contamination pass through the system while the unit is off.

Do I need to worry about the quality of my water prior to the UV?

For UV to be effective, it is recommended that the influent water contain less than the following:

iron less than 0.3 ppm

hydrogen sulphide less than 10 ppm

suspended solids less than 10 ppm

manganese less than 0.05

ppm hardness less than 7 gpg.

All conditions are treatable. To obtain adequate water quality for the UV, please consult your local water treatment professional for further assistance. To validate the disinfection process, it is important to have the water tested for bacteriological contaminants on a regular basis.

Why Ultraviolet?

Ultraviolet is a safe, clean, easy to maintain method of assuring that water is free of bacteria. It is a proven technology that has no significant drawbacks. In some applications, its initial cost is a bit more than chlorination, but because of its low operating cost, it quickly pays for itself. It is essentially trouble-free. Most systems require only an annual change of lamp--like changing a light bulb--and a change of filter cartridges if the unit has accompanying filters.

RFQ:

There are some details that i should confirm with your before our

design and quote.

01.What is the source of raw water to be treated?

--is it underground water or well water?or river water ,other source?

02.What is the capacity(m3/hour) you required for this sterilizer?

--most IMPORTANT requirement.

03.What will the treated water be used for?

--for human drinking or industry purpose?

| Model | Amount of disinfectant | Power (W) | Incoming and outcoming water pipes (Nominal/ British system) | System pressure resistance (Kg/cm²) | UV light fault Alarm | Dimension of the reactor (cm) L×W×H | Dimension of the control cabinet (cm) | Anchor screws | Transport weight(Kg) |

| YLCn-005 | 0.3 | 16 | 1/2″ | 6 | Has | 30×6×11 | 5 | ||

| YLCn-008 | 1 | 25 | 1/2″ | 6 | Has | 47×6.3×11 | 10 | ||

| YLCn-050 | 2 | 40 | 1″ | 6 | Has | 100×9×20 | Φ8.9×25 (d×L) | 69×4×Φ1 | 25 |

| YLCn-150 | 6 | 80 | 1+1/4″ | 6 | Has | 100×11×23 | 69×4×Φ1 | 30 | |

| YLCn-200 | 8 | 120 | 1+1/2″ | 6 | Has | 100×15.9×30 | Φ8.9×45 (d×L) | 69×7×Φ1 | 35 |

| YLCn-300 | 12 | 160 | 2″ | 6 | Has | 100×15.9×32 | 69×7×Φ1 | 40 | |

| YLC-050 | 2 | 40 | DN25/1″ | 6 | Has | 100×8.9×30 | 25×30×12 (W×H×D) | 60×4×Φ1 | 45 |

| YLC-150 | 6 | 80 | DN32/11/4″ | 6 | Has | 100×10.8×30 | 60×4×Φ1 | 50 | |

| YLC-200 | 8 | 120 | DN40/11/2″ | 6 | Has | 100×15.9×40 | 60×7×Φ1 | 60 | |

| YLC-300 | 12 | 160 | DN50/2″ | 6 | Has | 100×15.9×40 | 60×7×Φ1 | 70 | |

| YLC-360 | 15 | 200 | DN65/21/2″ | 6 | Has | 100×15.9×40 | 60×7×Φ1 | 120 | |

| YLC-500 | 20 | 240 | DN65/21/2″ | 6 | Has | 100×21.9×50 | 60×11×Φ1.2 | 130 | |

| YLC-600 | 25 | 280 | DN80/3″ | 6 | Has | 100×21.9×50 | 60×11×Φ1.2 | 140 | |

| YLC-700 | 30 | 320 | DN100/4″ | 6 | Has | 100×21.9×50 | 60×11×Φ1.2 | 150 | |

| YLC-1000 | 40 | 360 | DN100/4″ | 6 | Has | 100×21.9×50 | 60×11×Φ1.2 | 160 | |

| YLC-1200 | 50 | 400 | DN125/5″ | 6 | Has | 100×21.9×50 | 60×11×Φ1.2 | 180 | |

| YLC-1500 | 60 | 420 | DN150/6″ | 6 | Has | 170×27.3×57 | 120×16×Φ1.4 | 210 | |

| YLC-2000 | 80 | 560 | DN150/6″ | 6 | Has | 170×27.3×57 | 120×16×Φ1.4 | 220 | |

| YLC-2500 | 100 | 700 | DN150/6″ | 6 | Has | 170×27.3×57 | 60×128×30 (W×H×D) | 120×16×Φ1.4 | 275 |

| YLC-3000 | 125 | 840 | DN150/6″ | 6 | Has | 170×27.3×57 | 120×16×Φ1.4 | 300 | |

| YLC-4000 | 150 | 1120 | DN200/8″ | 6 | Has | 173×32.5×65 | 120×20×Φ1.6 | 325 | |

| YLC-5000 | 200 | 1400 | DN200/8″ | 6 | Has | 173×37.7×72 | 120×22×Φ1.6 | 350 | |

| YLC-7000 | 300 | 2100 | DN250/10″ | 6 | Has | 175×42.6×80 | 120×24×Φ2.0 | 400 | |

| YLC-10K | 400 | 2520 | DN250/10″ | 6 | Has | 176×52.9×95 | 60×150×40 (W×H×D) | 120×22×Φ2.2 | 475 |

| YLC-15K | 600 | 3080 | DN300/12″ | 6 | Has | 176×78×110 | 120×32×Φ2.4 | 600 | |

| YLC-20K | 800 | 3920 | DN350/14″ | 6 | Has | Designated | Designated | Designated | Designated |

| YLC-25K | 1000 | 4760 | DN350/14″ | 6 | Has | Designated | Designated | Designated | Designated |

Product Categories : Ultraviolet Sterilizer > UV Water Sterilizer

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)