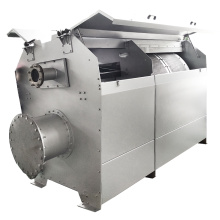

Cooling Tower Particals Removing Automatic Suction Cleaning Brush Filter

Basic Info

Model No.: YL-X-200

Product Description

Model NO.: YL-X-200 Working Pressure: 0.6/1.0/1.6MPa Filtration Degree: 100--600 Micros Specification: to be practical HS Code: 842121999 Material: Carbon Steel,Ss304,Ss316 Control: PLC Trademark: YLD Origin: Jiangyin, China

Working principle

When water flows into the entrance, the rough filtering net will filter out larger particles of impurities, it reaches the fine screen. During the process of filtering, fine screen gradually accumulate the dirt and impurities in water, then form a filtration impurity layer, as the impurity layer is stacked on the inside of the fine filtration screen. Therefore there will form a pressure differential between the inside and outer side of the fine screen.

When pressure differential of the filter reaches the preset value, it will start the automatic cleaning, during this process water supplying is constant, clearing valve opens, pressure in cleaning room and suction dirt device drops sharply, under the action of pressure difference between the filter cartridge and the sewage suction pipe, it will generate a suction between sewage suction pipe and the cleaning chamber through nozzle, a sewage suction process is finished. Meanwhile, the electric motor drives the sewage suction pipe to start a helical movement along the axis. The combine of sewage suction device axial motion and rotary motion will completely clean the inside surface of the screen, the flushing process will last 40 seconds to 1 minute. Drain valve will be closed at the end of clean process, filter will prepare next cleaning cycle.

Cleaning system

When the water flows through the filter, impurities will gradually accumulates in the surface of its screen, results in the water pressure difference between the water inlet pipe and outlet pipe. When the differential pressure reaches a preset value 0.05MP, backwashing starts work. Sucking scanner driven by motor, and do spiral motion around the screen, on the scanner suction by sucking impurity particle movement, through the sewage discharge valve, but does not contact the screen, the cleaning process for 30-60 seconds. According to the requirement of the water quality, suction type (500-30 micron) a variety of filtering accuracy.

Control mode

The filter is equipped with pressure difference switch and integrated controller. When water pressure difference reaches the preset value, the differential pressure switch will start, electric control system enter into the back wash process. The back wash time can be preset by the integrated controller.

Characteristic

1. The equipment structure is compact, sturdy and reliable

2. Back wash water consumption is small, and the required water pressure is low.

3. Filtering has high precision, is suitable for various water quality

4. The pressure drop is small while back wash, does not affect the normal water supply.

Max water temperature: 65 degree(special requirements could be up to 100 degrees)

Back flushing time: 60-120seconds

Water consumption for back flushingAbout 500Kg

Power supply: 380V, 50Hz, 3phase, Controller 220V

Motor powerSuction type: 0.37Kw

Filter shell: Carbon shell and resin coating

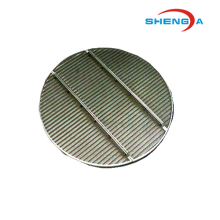

Filter cartridge: 304, 316 stainless steel (weaving, sintering, this form)

Outfall valve: Cast iron surface resin coating

Parameters sheet for horizontal type.

Contact us if you need more details on Brush Cleaning Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Suction Filter、Suction Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Working principle

When water flows into the entrance, the rough filtering net will filter out larger particles of impurities, it reaches the fine screen. During the process of filtering, fine screen gradually accumulate the dirt and impurities in water, then form a filtration impurity layer, as the impurity layer is stacked on the inside of the fine filtration screen. Therefore there will form a pressure differential between the inside and outer side of the fine screen.

When pressure differential of the filter reaches the preset value, it will start the automatic cleaning, during this process water supplying is constant, clearing valve opens, pressure in cleaning room and suction dirt device drops sharply, under the action of pressure difference between the filter cartridge and the sewage suction pipe, it will generate a suction between sewage suction pipe and the cleaning chamber through nozzle, a sewage suction process is finished. Meanwhile, the electric motor drives the sewage suction pipe to start a helical movement along the axis. The combine of sewage suction device axial motion and rotary motion will completely clean the inside surface of the screen, the flushing process will last 40 seconds to 1 minute. Drain valve will be closed at the end of clean process, filter will prepare next cleaning cycle.

Cleaning system

When the water flows through the filter, impurities will gradually accumulates in the surface of its screen, results in the water pressure difference between the water inlet pipe and outlet pipe. When the differential pressure reaches a preset value 0.05MP, backwashing starts work. Sucking scanner driven by motor, and do spiral motion around the screen, on the scanner suction by sucking impurity particle movement, through the sewage discharge valve, but does not contact the screen, the cleaning process for 30-60 seconds. According to the requirement of the water quality, suction type (500-30 micron) a variety of filtering accuracy.

Control mode

The filter is equipped with pressure difference switch and integrated controller. When water pressure difference reaches the preset value, the differential pressure switch will start, electric control system enter into the back wash process. The back wash time can be preset by the integrated controller.

Characteristic

1. The equipment structure is compact, sturdy and reliable

2. Back wash water consumption is small, and the required water pressure is low.

3. Filtering has high precision, is suitable for various water quality

4. The pressure drop is small while back wash, does not affect the normal water supply.

Max water temperature: 65 degree(special requirements could be up to 100 degrees)

Back flushing time: 60-120seconds

Water consumption for back flushingAbout 500Kg

Power supply: 380V, 50Hz, 3phase, Controller 220V

Motor powerSuction type: 0.37Kw

Filter shell: Carbon shell and resin coating

Filter cartridge: 304, 316 stainless steel (weaving, sintering, this form)

Outfall valve: Cast iron surface resin coating

Parameters sheet for horizontal type.

| Model | capacity(m³/Hr) | water Inlet & outlet | Drain pipe(mm) | Weight(Kg) | |

| mm | inch | ||||

| YL-X-50 | 19 | 50 | 2 | DN25 | 85 |

| YL-X-80 | 50 | 80 | 3 | DN25 | 87 |

| YL-X-100 | 80 | 100 | 4 | DN25 | 210 |

| YL-X-125 | 125 | 125 | 5 | DN32 | 212 |

| YL-X-150 | 180 | 150 | 6 | DN32 | 212 |

| YL-X-200 | 320 | 200 | 8 | DN40 | 220 |

| YL-X-250 | 490 | 250 | 10 | DN50 | 395 |

| YL-X-300 | 710 | 300 | 12 | DN50 | 405 |

| YL-X-350 | 970 | 350 | 14 | DN65 | 625 |

Contact us if you need more details on Brush Cleaning Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Suction Filter、Suction Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Filter > Automatic Self Cleaning Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)