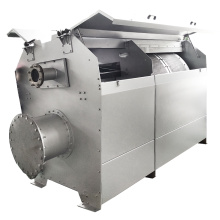

Stainless Steel Brush Suction Filtration

Basic Info

Model No.: YLXS-100

Product Description

Model NO.: YLXS-100 Usage: Environmental Protection, Chemical Industry Style: Vertical Certification: CE Product Name: Slef-Cleaning Brush Suction Filter Flow Rate: 19-1000m3/H Working Temperature: Less Than 100 Centigrade Filtering Precision: 20-500mm Use: Industy Water Filtration Specification: CE, SGS HS Code: 8421219990 Type: Filter Motive Force: Pressure Performance: Efficient Filtration Model: Ylxs-100 Material: Carbon Steel/Stainless Steel Working Pressure: Less Than 1.0 MPa Pressure Loss: Less Than 0.015MPa Interface: Flange Trademark: YLD Origin: Jiangyin, Jiangsu, China

What is an Automatic Filter?

filter is self cleaning and operates on line pressure alone, eliminating the need for an external power source. As water passes through the Water Filter, the dirt particles are collected on the screen. This causes a drop in water pressure. When the pressure drop reaches a preset level, the cleaning cycle is initiated. The Vacuum Screen Cleaner aggressively suctions the dirt from the inside of the screen and flushes it out the drain.

Standard Features:

Inlet/outlet on an axis of 90° (horizontal or vertical)

Strainer housing material of construction: Carbon Steel

- Strainers are electrostatically coated with polyester at a thickness of 150-200 micron and oven cured.

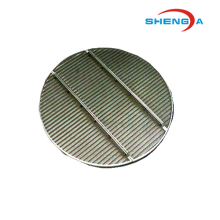

Strainers are supplied with a stainless steel wedgewire screen, available in varying micron size as needed: 200-4000 micron.

Inlet/outlet: Flanged 4" - 16"

Maximum recommended working pressure: up to 10 bar (150 psi)

Minimum operating working pressure during flushing: 1 bar (15 psi)

Clean screen pressure loss: up to 0.1 bar (1.5 psi)

Control voltage: 380/220 VAC, 3 phase, 0.5 HP motor

Control system: electric control board 380/220/120/24 VAC

A time basis backup (preset by the operator) guarantees that the flushing cycle will occur even if the head loss has not triggered a flush cycle.

Continuous filtration, flow direction inside to out side, welded wedge wire filter element, continuous cleaning of filter element by motor driven rotating brushes, automatic discharging of dirty slurry based on preset timer and or preset differential pressure, custom designed to suitable pressure / flow / micron rating.

The backwash cycle is accomplished in seconds without interrupting the main flow.

This technology can be used in cooling water filters, Water Tank filters, chiller water filters, sugar juice filters, sand filters, well water filters, r/o prefiltration, spray nozzle protection, white water filters, gland seal filters, screen water filters, industrial water filters, automatic strainers, and much much more.

Automatic Brush Strainers combine the advantages of high quality particle removal from different water sources (sewage, reservoirs, rivers, lakes, etc.) with a self-cleaning feature that provides a continuous water supply. The strainers are designed for use in a wide range of industrial, municipal and irrigation applications and are ideal as an automatic pre-strainer to the V-Series filters.

The wedgewire screen is made of 316L stainless steel in order to withstand high dirt load and pressure. Cleaning of the screen is performed once the pressure loss (ΔP) across the filter has reached the pre-set value [up to 0.5 bar (7 psi)].

The flushing valve opens and pressure in the strainer body is significantly lowered resulting in a suction process through the flush valve. The electric motor simultaneously rotates the stainless steel brushes to remove debris from the screen effectively. The whole process takes 8-10 seconds, and the water supply is uninterrupted.

Work principle

The filtered liquid gets into the filter from the entrance and into the strainer from the lower plate. The liquid flows from the inner side of the strainer to the outer side and gets out from the filter through the exit of the filter cartridge. The impurity from the backwashing is drained from the drainage entrance.

Process description

When the liquid flows from the inner side of the strainer to the outer side, the solid grain was held in the inner side of the strainer. With the increase of the pollutant, the pressure difference between the polluted side and the clean side is also growing. When the pressure difference reaches the set value, the automatic backwashing will start to work.

Design feature of the multi— Core self— Cleaning filter

1. The filter takes the internal mechanical structure of self-cleaning to realize the backwashing function in the true sense. It could clean the impurity on the strainer thoroughly. There is no dead angle for washing and no flux attenuation so that the filtering efficiency and the service life are assured.

2. The filter takes the wedge strainer of 304, 316L stainless steel with high strength, precision and corrosion resistance. The filtering precision is 251im.

3. The filter with few wearing parts, no consumable, low maintenance cost. The operation and management are simple.

4. The control system of the filter is with sensitive response and precise operation. The backwashing pressure difference and the time could be adjusted flexibly according to the different water source and filtering precision.

Technical parameters:

Application

commercial offices and the hotel sector, various benefits for swimming pools and the leisure industry, cooling towers of all sizes, food processing, agricultural and manufacturing industries. We also cover more specialized applications such as mining, water transport and power stations.

The circulated or non-circulated cooling water system, heat exchange system, central air conditioning system and central heating system in the industries like architecture, chemistry, metallurgy, rubber, paper making, light textile, coal and foods, used to protect the cooling equipment, heat exchange device and air conditioner accordingly. Contact us if you need more details on Brush Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sand Filter、Active Carbon Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

What is an Automatic Filter?

filter is self cleaning and operates on line pressure alone, eliminating the need for an external power source. As water passes through the Water Filter, the dirt particles are collected on the screen. This causes a drop in water pressure. When the pressure drop reaches a preset level, the cleaning cycle is initiated. The Vacuum Screen Cleaner aggressively suctions the dirt from the inside of the screen and flushes it out the drain.

Standard Features:

Inlet/outlet on an axis of 90° (horizontal or vertical)

Strainer housing material of construction: Carbon Steel

- Strainers are electrostatically coated with polyester at a thickness of 150-200 micron and oven cured.

Strainers are supplied with a stainless steel wedgewire screen, available in varying micron size as needed: 200-4000 micron.

Inlet/outlet: Flanged 4" - 16"

Maximum recommended working pressure: up to 10 bar (150 psi)

Minimum operating working pressure during flushing: 1 bar (15 psi)

Clean screen pressure loss: up to 0.1 bar (1.5 psi)

Control voltage: 380/220 VAC, 3 phase, 0.5 HP motor

Control system: electric control board 380/220/120/24 VAC

A time basis backup (preset by the operator) guarantees that the flushing cycle will occur even if the head loss has not triggered a flush cycle.

Continuous filtration, flow direction inside to out side, welded wedge wire filter element, continuous cleaning of filter element by motor driven rotating brushes, automatic discharging of dirty slurry based on preset timer and or preset differential pressure, custom designed to suitable pressure / flow / micron rating.

The backwash cycle is accomplished in seconds without interrupting the main flow.

This technology can be used in cooling water filters, Water Tank filters, chiller water filters, sugar juice filters, sand filters, well water filters, r/o prefiltration, spray nozzle protection, white water filters, gland seal filters, screen water filters, industrial water filters, automatic strainers, and much much more.

Automatic Brush Strainers combine the advantages of high quality particle removal from different water sources (sewage, reservoirs, rivers, lakes, etc.) with a self-cleaning feature that provides a continuous water supply. The strainers are designed for use in a wide range of industrial, municipal and irrigation applications and are ideal as an automatic pre-strainer to the V-Series filters.

The wedgewire screen is made of 316L stainless steel in order to withstand high dirt load and pressure. Cleaning of the screen is performed once the pressure loss (ΔP) across the filter has reached the pre-set value [up to 0.5 bar (7 psi)].

The flushing valve opens and pressure in the strainer body is significantly lowered resulting in a suction process through the flush valve. The electric motor simultaneously rotates the stainless steel brushes to remove debris from the screen effectively. The whole process takes 8-10 seconds, and the water supply is uninterrupted.

Work principle

The filtered liquid gets into the filter from the entrance and into the strainer from the lower plate. The liquid flows from the inner side of the strainer to the outer side and gets out from the filter through the exit of the filter cartridge. The impurity from the backwashing is drained from the drainage entrance.

Process description

When the liquid flows from the inner side of the strainer to the outer side, the solid grain was held in the inner side of the strainer. With the increase of the pollutant, the pressure difference between the polluted side and the clean side is also growing. When the pressure difference reaches the set value, the automatic backwashing will start to work.

Design feature of the multi— Core self— Cleaning filter

1. The filter takes the internal mechanical structure of self-cleaning to realize the backwashing function in the true sense. It could clean the impurity on the strainer thoroughly. There is no dead angle for washing and no flux attenuation so that the filtering efficiency and the service life are assured.

2. The filter takes the wedge strainer of 304, 316L stainless steel with high strength, precision and corrosion resistance. The filtering precision is 251im.

3. The filter with few wearing parts, no consumable, low maintenance cost. The operation and management are simple.

4. The control system of the filter is with sensitive response and precise operation. The backwashing pressure difference and the time could be adjusted flexibly according to the different water source and filtering precision.

Technical parameters:

| Model | Flow (T/h) | Inlet and outlet diameter (mm) | Drainage diameter (mm) | D (mm) | H (mm) | H1 (mm) | H2 (mm) |

| YLF-50 | 70 | DN50 | DN50 | 300 | 1690 | 265 | 640 |

| YLF-80 | 80 | DN80 | DN50 | 350 | 1720 | 265 | 660 |

| YLF-100 | 120 | DN100 | DN50 | 400 | 1760 | 265 | 680 |

| YLF-200 | 200 | DN200 | DN80 | 500 | 1860 | 290 | 715 |

| YLF-250 | 280 | DN250 | DN80 | 600 | 1930 | 290 | 755 |

| YLF-300 | 450 | DN300 | DN100 | 700 | 2040 | 335 | 755 |

| YLF-350 | 600 | DN350 | DN100 | 800 | 2105 | 335 | 770 |

| YLF-400 | 800 | DN400 | DN100 | 1000 | 2220 | 335 | 800 |

| YLF-500 | 1000 | DN500 | DN100 | 1200 | 2360 | 365 | 825 |

Application

commercial offices and the hotel sector, various benefits for swimming pools and the leisure industry, cooling towers of all sizes, food processing, agricultural and manufacturing industries. We also cover more specialized applications such as mining, water transport and power stations.

The circulated or non-circulated cooling water system, heat exchange system, central air conditioning system and central heating system in the industries like architecture, chemistry, metallurgy, rubber, paper making, light textile, coal and foods, used to protect the cooling equipment, heat exchange device and air conditioner accordingly. Contact us if you need more details on Brush Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sand Filter、Active Carbon Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Filter > Automatic Self Cleaning Filter

Premium Related Products

Other Products

Hot Products

Air Conditioner Condenser Tube Cleaning EquipmentChilled Water Treatment Rapid Quartz Sand FilterHair Collector Filter for Swimming PoolPool Disinfection Water System Chlorine Dioxide GeneratorSUS 304 Bag Filter Housing and PP Filtering Cartridgeby Pass Flow Water Processor Side Stream Treatment (YLD-II-G)Stainless Steel or Carbon Steel Swimming Pool Hair FilterElectromagnetic Water Treatment with High FrequencyYlc-200 Immersion Ultraviolet Sterilizer Water Purifier Without Secondary PollutionOpen Channel UV Water Sterilizer System with Automatic ControlAuto Cleaning Brush Type Water Filter for 100/200 Micron Coarse Filtration10000 Gauss Strong Water Magnetic Treatment Filter in Agriculture DesalinationStainless Steel Bag Filter Housing 0.5um Liquid Filtration Water PurifcationIndustrial Water UV Sterilizer, Water Purifying UV Light SterilizerAutomatic Backwash Self Cleaning Stainless Steel Cartridge Water FilterCirculating Water System Automatic Sand Media Water Filter (YL-SF-500)